Why Early Mold Decisions Often Lock in Costs During Production Ramp-Up

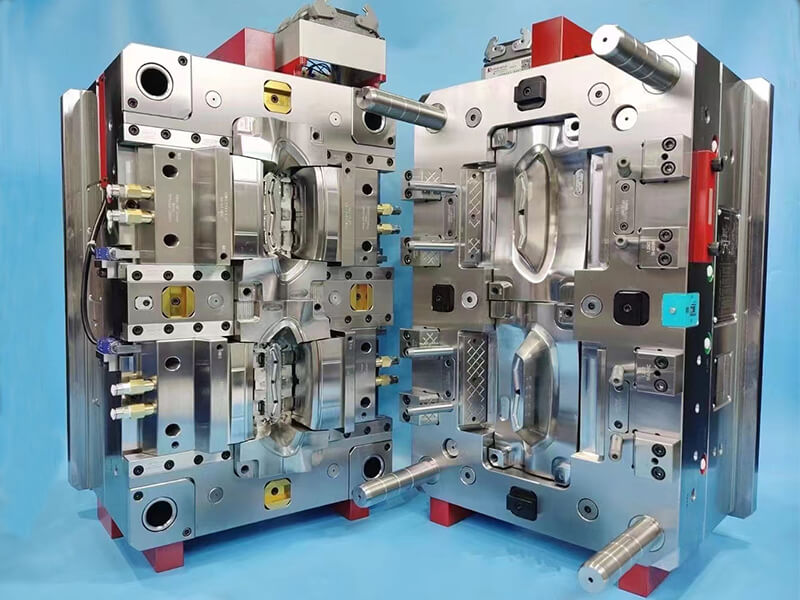

In injection molding, early mold decisions lock production ramp-up costs — often leading to budget overruns and delays when scaling. Learn how to avoid these costly traps with forward-thinking mold design strategies.