Our Services

这是测试文本,单击 “编辑” 按钮更改此文本。

One-Stop Manufacturing for PCB, Plastic & Final Assembly.

From concept to global delivery, we provide integrated manufacturing solutions that ensure reliability, compliance, and cost efficiency.

Our One-Stop Manufacturing Services

From design and tooling to injection molding, PCB assembly, testing, and packaging — all under one roof.

Product Design Support

- 3D modeling & DFM optimization

- Rapid prototyping & validation

- Design aligned with manufacturability

Mold Fabrication

- High-precision CNC & EDM machining

- Durable tooling with tight tolerances

- Mirror finishing & steel polishing

Injection Molding

- Single & two-shot molding solutions

- Precision housings and functional parts

- Stable quality with automation control

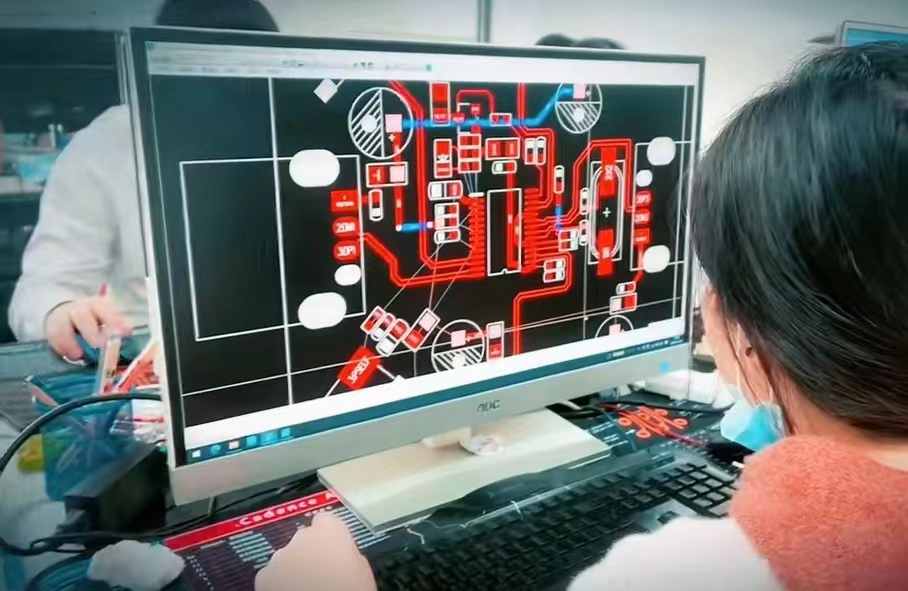

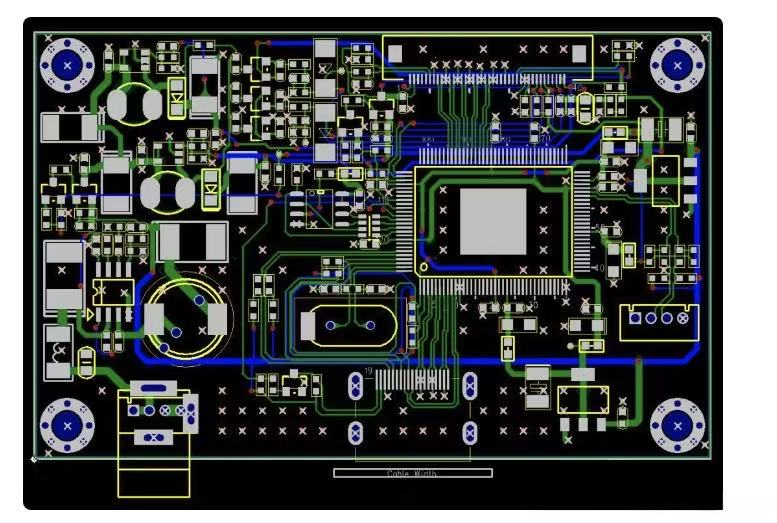

PCB Design & Layout

- Schematic & multilayer layout

- Signal integrity & stack-up planning

- Manufacturability optimization

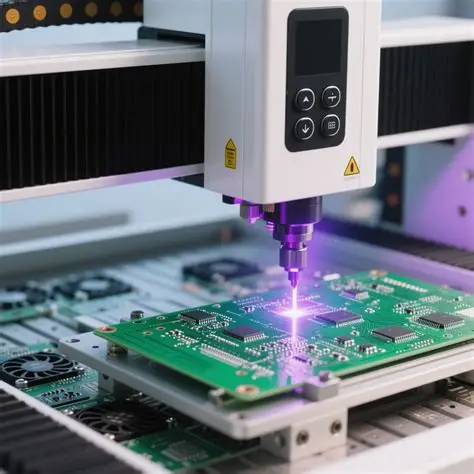

SMT Assembly

- High-speed placement & reflow soldering

- Automatic SPI, AOI inspection

- Stable yield for complex boards

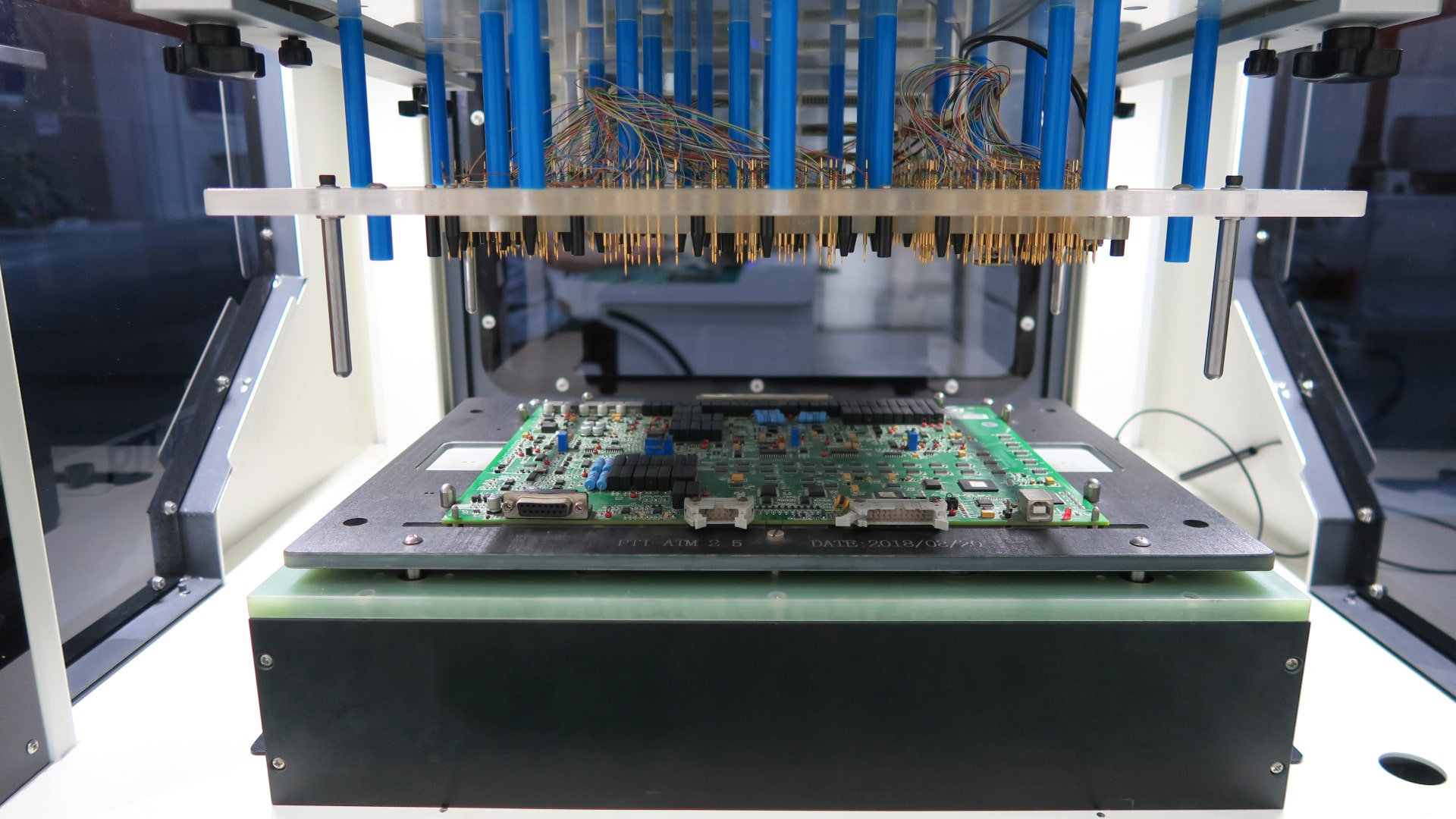

Testing & Validation

- ICT, AOI & functional tests

- Reliability & burn-in verification

- Compliance: CE, FCC, UL ready

Product Assembly

- Plastic + PCB integrated assembly

- System integration & ESD protection

- Functional and aging testing

Packaging & Shipping

- Final inspection & labeling

- Protective ESD-safe packaging

- Global delivery & logistics support

WHY CHOOSE US

Reliable Manufacturing, Transparent Quality, and Long-Term Partnership

With advanced manufacturing, integrated engineering, and a global service mindset, we deliver precision, reliability, and value at every stage — from concept to mass production.

01 One-Stop Manufacturing

- All in-house — from mold, injection, PCB, SMT to final assembly.

- Short lead times through parallel production workflow.

- Fewer handoffs reduce coordination cost and quality risk.

02 Strict Quality Control

- AOI / ICT / Functional Tests at every stage of production.

- Full traceability from materials to final shipment.

- Certified under ISO9001, ISO13485, CE, and UL systems.

03 Fast Turnaround

- Rapid prototyping and pilot runs for faster validation.

- Smart planning ensures stable schedules and delivery.

- Flexible capacity from small runs to large batches.

04 Global Delivery Support

- Worldwide logistics with full export documentation.

- ESD-safe packaging and humidity control for electronics.

- Responsive service with after-sales technical follow-up.

05 Experienced Engineering Team

- Cross-functional expertise in plastics, PCBA, and assembly design.

- DFM / DFA reviews help customers optimize products early.

- Direct technical communication with mechanical & electronic engineers.

06 Sustainability & Reliability

- RoHS & REACH compliance with eco-friendly material sourcing.

- Energy-efficient processes across molding and assembly lines.

- Long-term reliability testing for durable end-use performance.

OUR TECHNICAL CAPABILITIES

Advanced PCB Manufacturing Expertise

From PCB fabrication and SMT assembly to testing and final assembly, our integrated manufacturing capabilities ensure performance, precision,

and speed across every production stage.

High-Precision PCB Fabrication

- ±0.05 mm precision in drilling, routing, and copper alignment ensures stable signal transmission and layer consistency.

- Laser Direct Imaging (LDI) with automatic impedance control guarantees uniform line width and minimal deviation in fine traces.

- Engineered for high-frequency, RF, and fine-pitch circuit designs used in communication and industrial control systems.

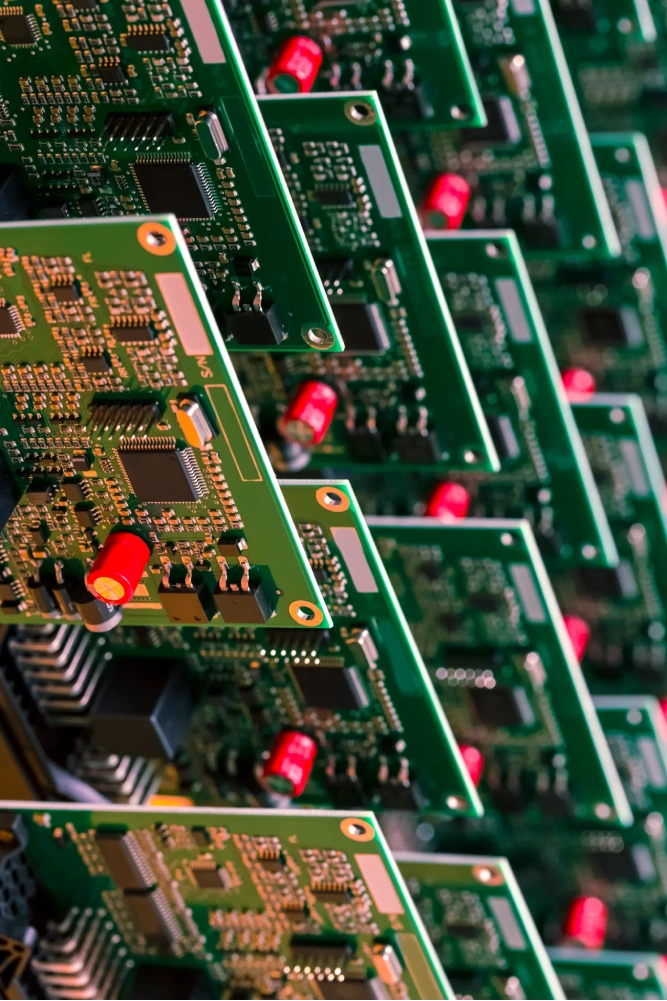

HDI & Multi-Layer PCB Manufacturing

- Supports up to 24 layers with blind & buried vias and laser-drilled microvias for complex interconnections.

- Fine line/space down to 75 μm with advanced lamination and vacuum press for dimensional stability.

- Ideal for miniaturized designs in IoT, automotive electronics, and high-density communication modules.

Advanced SMT Assembly

- High-speed placement for 01005 components with ±25 μm alignment using automated optical calibration.

- Integrated 3D SPI, AOI, and X-ray inspection ensure zero-defect solder joints and consistent reliability.

- Flexible assembly processes combining SMT + THT + press-fit for mixed-technology product builds.

Comprehensive Testing & Quality Validation

- 100% testing coverage through ICT, AOI, and functional tests to eliminate defects before shipment.

- Reliability validation includes vibration, thermal shock, and aging tests for long-term product stability.

- Digital traceability system provides real-time data tracking and detailed quality reports for every lot.

Engineering & DFM Support

- Early manufacturability review (DFM/DFA) to optimize yield, cost, and production efficiency before tooling starts.

- Customized stack-up design and material selection for impedance, thermal, or mechanical requirements.

- Dedicated engineering team provides design feedback and process simulation within 24 hours.

Final Assembly & Global Delivery

- Complete box-build assembly including conformal coating, cable harnessing, and functional testing.

- ESD-protected workstations and export-ready documentation for safe global shipments.

- Worldwide logistics support ensures on-time delivery and traceability from factory to customer.

Manufacturing Case Highlights

High-Density PCB for IoT Module

Challenge

The customer required a compact, multi-layer PCB with high signal integrity for an IoT gateway device.

Solution

We produced 12-layer HDI PCBs using laser microvias and impedance-controlled stack-up to ensure stable data transmission.

Result

Improved signal quality by 25% and reduced EMI noise, enabling mass production in just 4 weeks.

Rapid Prototype Assembly

Challenge

A startup needed fully functional prototypes within 7 days for investor demo and certification testing.

Solution

Integrated PCB manufacturing, SMT, and assembly in one workflow to shorten lead time while maintaining full traceability.

Result

Delivered 10 prototype units in 6 days — passed initial CE pre-tests and accelerated time-to-market by 40%.

Reliability Testing for Medical PCB

Challenge

The client needed long-term durability validation for PCBs used in portable health monitoring devices.

Solution

Conducted vibration, thermal shock, and aging tests under IEC standards with complete inspection documentation.

Result

All samples passed 500-hour reliability tests with zero failure — approved by client’s compliance audit team.

WHAT OUR CLIENTS SAY

Client Feedback You Can Rely On

From global brands to fast-growing startups, our partners trust CINDY Mould for consistent quality, smooth communication, and dependable delivery.

“CINDY Mould’s PCB and assembly services helped us scale production faster than expected. Quality was consistent and documentation clear throughout the process.”

Lucas W. | Electronics OEM | USA

“Their engineering team supported us from design review to shipment. Every DFM suggestion saved both cost and assembly time — a true one-stop partner.”

Emily T. | Smart Home Brand | Germany

“Stable quality, precise assembly, and excellent logistics coordination. CINDY Mould delivered our industrial controller housings right on schedule.”

Kenji H. | Industrial Automation | Japan

FREQUENT QUESTIONS

FAQ

Find answers to common questions about our PCB manufacturing, assembly, and delivery services. For anything not listed, our team is always here to assist you.

For standard PCB production, our typical lead time is 7–12 working days. Prototype orders can be completed within 5 days depending on design complexity.

Yes. Our engineering team performs a Design for Manufacturability (DFM) check before tooling starts to ensure optimal yield and reliability.

Absolutely. We specialize in both prototype and low-to-medium volume production to support early design validation and fast iteration.

All boards and assemblies undergo AOI, ICT, and functional tests. We provide complete inspection reports and traceable data for every production lot.

Yes, we offer turnkey component sourcing through approved vendors, ensuring traceability, cost efficiency, and consistent quality.

Yes, we ship worldwide. Our logistics team supports DDP, EXW, and FOB delivery terms with full export documentation and tracking.

Your Next Great Product Starts Here

Get a quote or technical review within 24 hours — trusted by global brands for precision manufacturing and fast delivery.

Contact Our Team- 24hEngineering Response

- 100+Successful Projects / Year

- 98%On-Time Delivery Rate