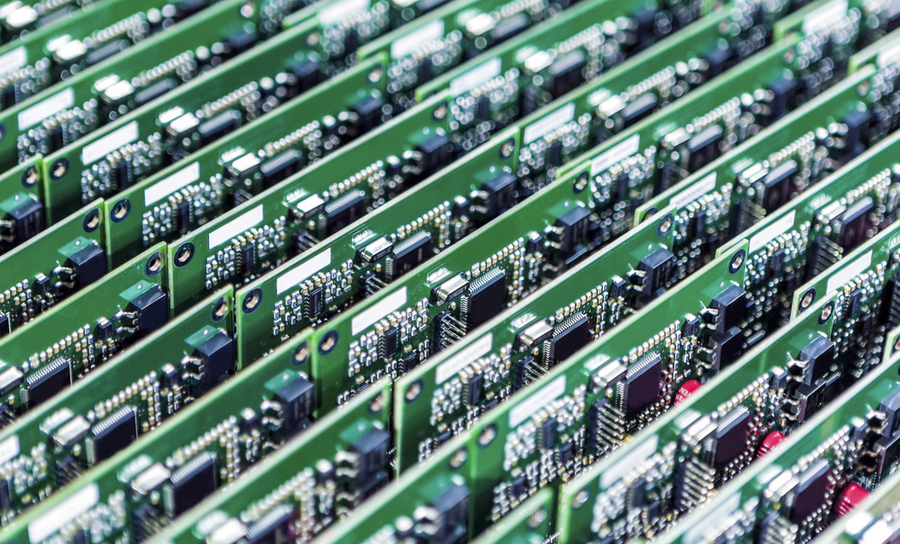

From Concept to Completed PCB Assembly

SMT, DIP, Testing and Final Assembly — All Under One Roof

Professional SMT & PCB assembly with speed, precision, and reliability.

From design verification to final assembly,

we deliver end-to-end manufacturing solutions for your electronics.

What is SMT Assembly

SMT Assembly, short for Surface Mount Technology Assembly, is a highly efficient method of mounting electronic components directly onto the surface of a printed circuit board (PCB). This process enables high-density circuit design, faster production speeds, and improved manufacturing automation. By using advanced pick-and-place machines and precise soldering techniques, SMT assembly achieves high precision and reliability, making it the preferred choice for modern electronics manufacturing across industries such as consumer electronics, automotive, medical devices, and telecommunications.

SMT Assembly Process: Step-by-Step Surface Mount Technology Workflow

1

Step 1 – Solder Paste Printing

In the SMT assembly process, solder paste is precisely printed onto the PCB pads using a stencil printer. This ensures accurate solder volume for each surface-mounted device (SMD).

2

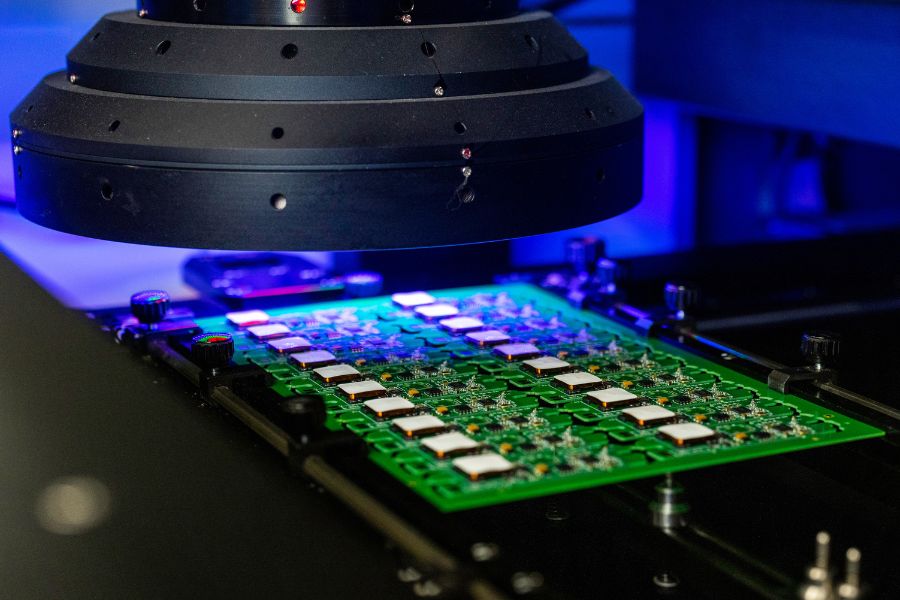

Step 2 – Component Placement

High-speed pick-and-place machines position SMD components onto the PCB according to the design file, ensuring high accuracy and efficiency.

3

Step 3 – Reflow Soldering

The assembled PCB is passed through a reflow oven where the solder paste melts and forms strong, reliable joints between components and pads.

4

Step 4 – Inspection and Quality Control

Automated Optical Inspection (AOI), X-ray inspection, and manual checks are performed to detect soldering defects and ensure assembly quality.

5

Step 5 – Final Processing

This includes cleaning, conformal coating, functional testing, and preparing the PCB assembly for the next stage such as DIP assembly or final product integration.

Key Advantages and Quality Assurance of SMT Assembly

High Speed Production

Automated pick-and-place machines ensure rapid and efficient SMT assembly, reducing lead times significantly.

Cost Efficiency

Optimized automated processes lower labor and material costs, delivering affordable solutions for all production volumes.

High Precision Reliability

State-of-the-art equipment and strict quality controls guarantee accurate component placement and durable solder joints.

Ideal for Modern Electronics

Supports high-density PCB designs and miniaturization, perfect for consumer electronics, automotive, medical, and telecom sectors.

Quality Assurance

Rigorous inspections including AOI, X-ray, and functional testing ensure consistent product quality and reliability.

Key Equipment and Technologies in SMT Assembly

Successful SMT PCB assembly relies on a series of specialized machines that work together to achieve speed, accuracy, and reliability. From solder paste printing to automated optical inspection, each piece of SMT equipment plays a critical role in producing high-quality electronic assemblies. Whether it’s high-speed pick-and-place machines for precision component placement or multi-zone reflow ovens for stable solder joints, investing in advanced SMT technology ensures maximum production efficiency and product reliability.

Solder Paste Printer

The solder paste printer applies solder paste onto PCB pads with high precision, ensuring optimal adhesion for components. Using advanced stencil alignment and 3D inspection, it guarantees uniform solder volume for high-quality SMT assembly.

Reflow Oven

A reflow oven melts the solder paste under controlled temperature profiles to create reliable solder joints. Multi-zone reflow ovens ensure consistent heating, making them essential for high-density and lead-free SMT assembly.

Conformal Coating Machine

Conformal coating machines apply a protective polymer layer to assembled PCBs, safeguarding them against moisture, dust, corrosion, and temperature extremes. This process enhances product reliability and extends the lifespan of electronic assemblies, especially in harsh environments.

Pick-and-Place Machine

The pick-and-place machine rapidly positions electronic components onto the PCB with micrometer accuracy. Modern SMT lines use high-speed models capable of handling fine-pitch packages, BGAs, and 01005 components for maximum production efficiency.

SPI – Solder Paste Inspection

The SPI machine uses 3D optical measurement to check solder paste height, volume, and shape before placement. This process prevents defects early in the SMT assembly line, reducing rework and improving yield rates.

PCB Handling System

PCB handling equipment, including loaders, unloaders, and conveyors, automates board movement between SMT processes. This improves workflow efficiency and reduces manual handling errors.

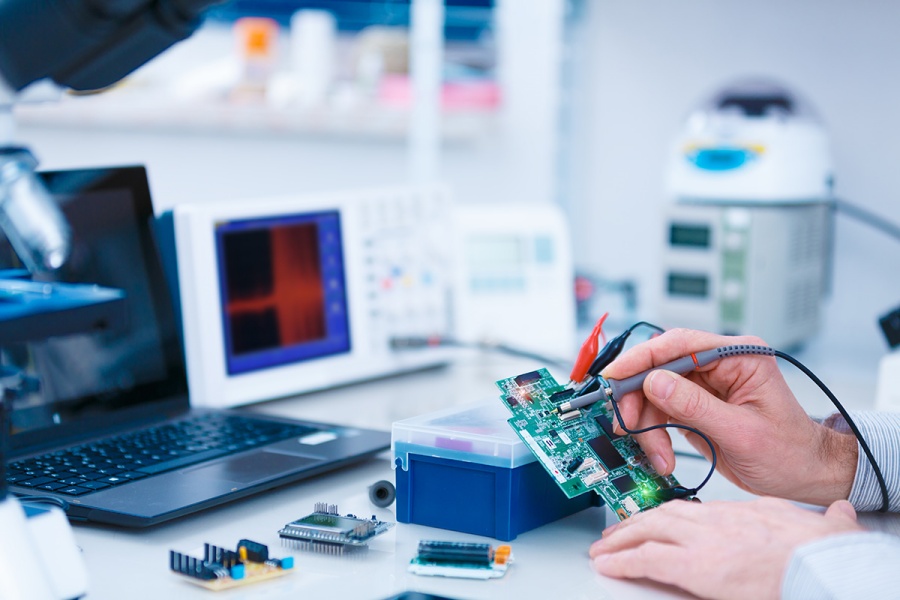

Ensuring Excellence: SMT Quality Control & Inspection

In our SMT PCB assembly process, every board undergoes a rigorous quality control workflow to guarantee reliability and performance. From AOI and X-ray inspection to functional testing and DFM/DFT analysis, we ensure that every product meets international quality standards before delivery.

AOI

AOI systems scan assembled PCBs to detect missing components, misalignment, and soldering defects. High-resolution cameras and AI algorithms ensure every board meets quality standards before shipment.

DFM / DFT Analysis

Conducts comprehensive design reviews to optimize PCB layouts for manufacturability and testability, identifying potential issues before production to reduce costs, improve yield rates, and streamline the assembly and inspection processes.

FCT

Verifies the electrical performance and functionality of the assembled circuit boards under simulated real-world operating conditions, ensuring they meet design specifications and reliability standards before shipment.

X-ray Inspection

Detects hidden soldering flaws and internal assembly defects beyond the reach of optical inspection, delivering essential quality control for BGA, QFN, and other compact component packages to ensure product durability.

Comprehensive SMT Assembly Service Process

At Cindy Mould, we provide a seamless one-stop SMT assembly service designed to ensure quality, efficiency, and customer satisfaction. Our well-defined process covers every stage from initial requirements gathering to final product delivery, allowing you to focus on your core business while we handle the complexities of electronics manufacturing.

Requirement Consultation

We work closely with you to understand your project specifications, volume needs, and deadlines, ensuring all technical and logistical details are clear from the start.

Design & Feasibility Assessment

Our engineering team reviews your PCB design and BOM (Bill of Materials) for manufacturability and cost optimization, providing expert recommendations to improve yield and reduce risk.

SMT Production

Utilizing advanced equipment and automated SMT lines, we precisely mount components, perform soldering, and conduct in-process inspections to maintain high production standards.

Quality Testing

Each assembled PCB undergoes rigorous quality control, including AOI, X-ray inspection, functional testing, and DFM/DFT checks, to guarantee reliability and compliance with industry standards.

Final Delivery & Support

We provide packaging, logistics coordination, and post-delivery technical support to ensure your products reach you on time and function flawlessly in your applications.

Ready to bring your project to life with top-tier SMT assembly?

Send us your BOM list or PCB design files today for a fast, accurate quote!

Our team is here to provide personalized support and competitive pricing tailored to your needs.