Rapid Prototyping

– PCB & Enclosure Samples

Validate your designs quickly and efficiently with our rapid prototyping services

Cindy Mould offer rapid prototyping services for both PCB and product enclosures,

helping you validate designs quickly and efficiently.

3D Printing

Vacuum Casting

PCB Prototyping

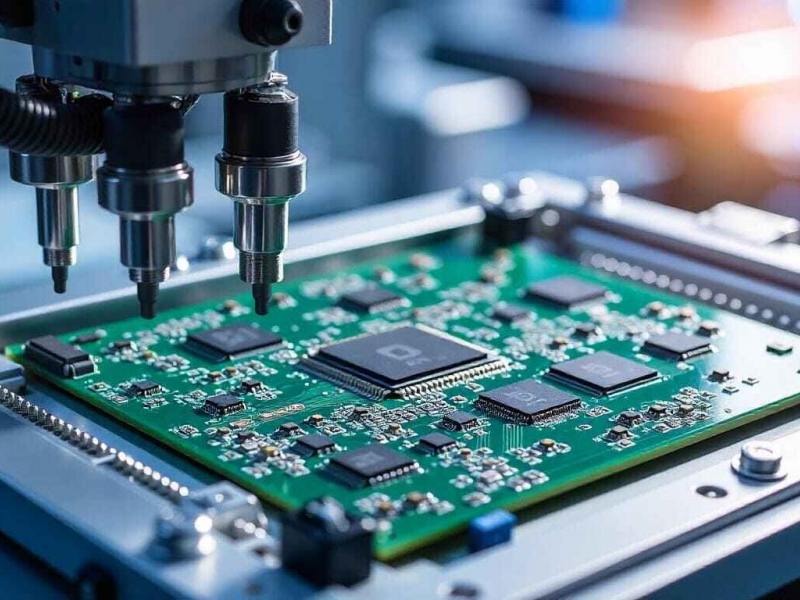

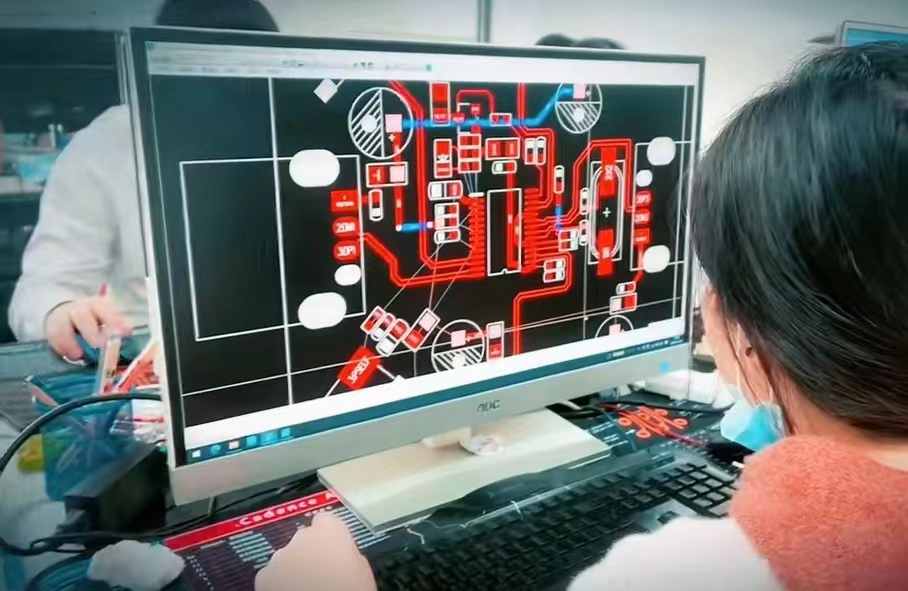

PCB Prototyping

We provide rapid PCB prototyping services for single-layer, double-layer, and multilayer boards, starting from just 1 pcs. In addition to PCB fabrication, we also offer SMT assembly and functional testing, enabling you to validate your electronic designs quickly and effectively.

Key Benefits:

Fast turnaround: PCB prototypes ready within 3–7 days

Low-volume flexibility: Cost-effective for R&D and pilot runs

Testing support: Optional SMT assembly and functional verification

Seamless scale-up: Smooth transition to mass production

Enclosure Prototyping

3D Printing

3D printing prototyping is an additive manufacturing process that builds parts layer by layer, ideal for enclosure samples, functional prototypes, and design validation. We support 1 pcs or low-volume production, with delivery as fast as 2–4 days.

Applications:

Product enclosure mockups (ABS, PLA, Nylon, and other engineering plastics)

Functional and structural testing models

Small-batch trial production

Key Benefits:

No tooling required: Rapid iterations with zero mold cost

Supports complex geometries: Perfect for customized and intricate designs

Low cost for small batches: Start from just one prototype

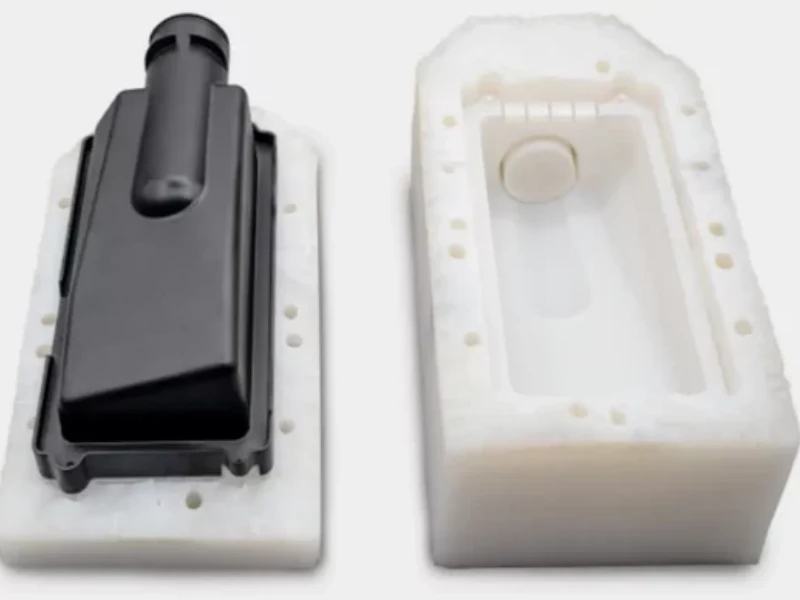

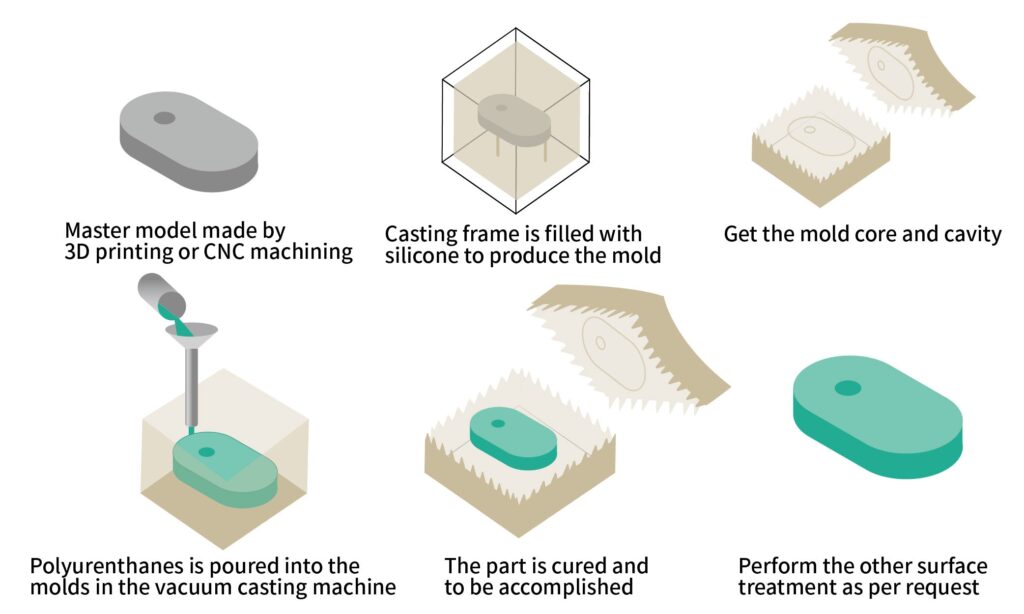

Vacuum Casting

Vacuum casting is a process that uses a silicone mold under vacuum to cast polyurethane or ABS-like resins. It is ideal for low-volume prototype production and can closely replicate the appearance and performance of injection-molded parts. Prototypes can be delivered within 5–7 days, Suitable for low-volume production from 10 to 100 pcs.

Applications:

Plastic enclosures for electronics and consumer products

Transparent or colored resin components

Assembly verification and functional testing

Key Benefits:

High fidelity: Replicates injection-molded surface finish and detail

Cost-effective low-volume runs: No need for expensive steel molds

Post-processing ready: Compatible with painting, plating, and silk-screen printing

Why Choose Our Rapid Prototyping

Fast Response

Quick communication to accelerate your design validation.

Low Small-Batch Cost

Efficient prototyping without high production expenses.

Scalable for Production

Seamlessly transition to mass production after prototyping.

Multiple Materials

Supports a wide range of PCB, plastic, and silicone materials.

Fast Turnaround

Prototype delivery within days, not weeks.

Design Optimization Support

Assistance with DFM and functional testing to refine your design.

FAQ

What is Rapid Prototyping?

Rapid prototyping is the process of quickly creating a sample or a few units of a product before full-scale production. It helps verify the design, manufacturing process, and functionality.

Why Do You Need Prototyping?

Prototyping helps identify design flaws, dimensional errors, or manufacturing issues early, reducing risks and costs in mass production.

What Types of Products Can Be Prototyped?

We offer rapid prototyping services for electronic product enclosures, plastic components, PCBA assemblies, and full product assembly, supporting various materials and manufacturing methods.

What Are the Benefits of Rapid Prototyping?

Cost Savings: Prevents expensive revisions during mass production

Faster Development: Quickly validates design and functionality

Product Optimization: Allows multiple iterations to improve the final product

How Long Does Rapid Prototyping Take?

Depending on product complexity and material choice, prototypes can typically be completed within a few days to a week, keeping your development timeline on track.

Can Prototypes Support Small-Scale Production?

Yes, prototypes are not only for design validation but can also serve as the starting point for small-scale production, ideal for market testing or client demonstrations.

Ready to bring your ideas to life?

We’ll guide you from concept to market success. Start your journey with us today.

Let’s build your product and success together

CINDY Mould — your trusted one-stop smart manufacturing partner worldwide.