Reliable Delivery, Built on Strict Process Control

Every batch of material and product can be traced from source to shipment.

Strict multi-stage inspections ensure reliable and consistent quality.

All products undergo full inspection before leaving the factory.

CINDY Mould is committed to delivering high-quality manufacturing and reliable delivery.

From raw material sourcing to final shipment, we implement strict quality control throughout the entire process, supported by standardized procedures and testing systems to ensure products

meet the stringent requirements of international clients.

Our Process

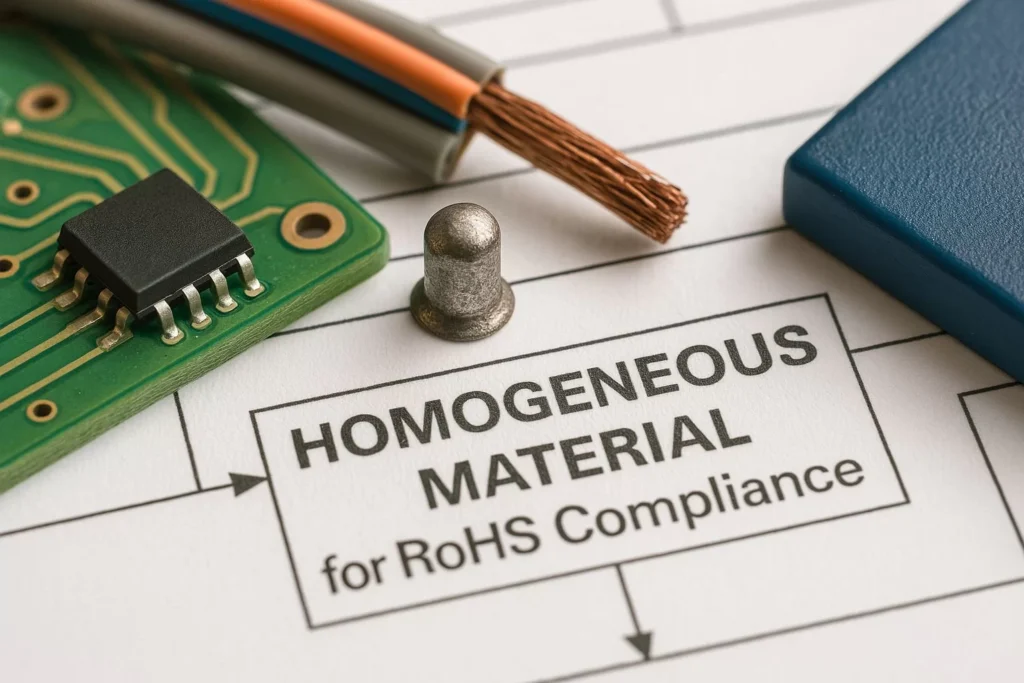

Material Sourcing Control

Ensure all raw materials come from qualified and reliable suppliers.

Provide material source certificates and conflict-free declarations.

Optional compliance with international standards such as RoHS and REACH.

Purpose: Prevent substandard materials from entering production, ensuring product reliability.

Incoming Inspection & Storage

Conduct IQC inspections for dimensions, functionality, and batch verification.

Store materials in moisture-proof and ESD-controlled environments.

Implement batch tracking systems to avoid mix-ups and maintain traceability.

Purpose: Guarantee consistent material quality and prevent production issues.

SMT Assembly & Checkpoints

Perform solder paste printing, component placement, reflow soldering, and AOI inspection.

Monitor key points: solder paste thickness, solder joint consistency, component alignment.

Conduct in-process inspections to catch defects early.

Purpose: Ensure PCB assembly quality and reduce rework or failures.

Standardized Product Assembly

Follow SOPs (Standard Operating Procedures) for consistent assembly.

Use jigs, fixtures, and ergonomic workstations to minimize human errors.

Include self-inspection and patrol inspections at every step.

Purpose: Maintain uniform assembly quality across all products.

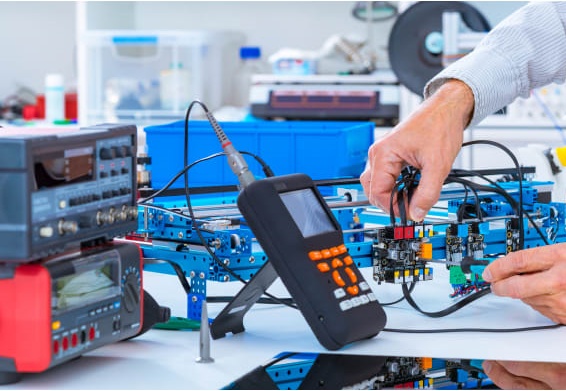

Functional Testing

Conduct ICT (In-Circuit Test) and FCT (Functional Test) to verify product performance.

Simulate real-world operating conditions to ensure stability.

Record data in real-time and immediately isolate defective units.

Purpose: Guarantee each product functions reliably before packaging.

Packaging Process

Use anti-static and moisture-proof materials; vacuum sealing when required.

Ensure packaging meets export standards and supports client-specific customization.

Conduct packaging inspections to verify protection and labeling accuracy.

Purpose: Safeguard products during transport and maintain quality until delivery.

Final Inspection & Shipment Tracking

Perform OQC (Outgoing Quality Control) inspections before shipping.

Assign unique tracking numbers to each product for traceability.

Optional third-party inspection reports (SGS, BV) available upon request.

Purpose: Confirm only fully compliant products reach the customer.

Certified Quality Management System

ISO9001:2015 Quality management system certification

High-Tech Enterprise Certification

ESD Control Standards

We comply with ANSI/ESD S20.20 and IEC 61340-5-1 requirements to protect sensitive electronic components.

Measures include anti-static wrist straps, ionizers, ESD flooring, and protective packaging.

Personnel Protection

Operators wear antistatic wrist straps and ESD-safe uniforms.

Workshop Environment

Anti-static flooring and grounded workstations.

Packaging Safety

Use of ESD shielding bags and moisture-proof packing.

Regular Monitoring

Continuous testing of grounding resistance and ESD equipment.

From Strict Control to Reliable Delivery

We ensure the reliability of every delivery by rigorously managing every process.

👉 Contact Us