Comprehensive Product Assembly for Precision & Quality

End-to-end product assembly: quality, speed, and reliability guaranteed.

Fast Facts

Key metrics reflecting our efficiency, precision, and quality commitment.

Typical Lead Time: 7–15 Days

🚀 Rapid prototyping for faster market entry.

🔄 Quick turnaround for small-batch assembly.

⚡ Streamlined workflow for shorter cycles.

⏳ Reduced waiting time for faster delivery.

High-Precision Assembly: ±0.05 mm

📡 Stable signal performance with minimal deviation.

🛠 Perfect for tight-tolerance complex modules.

💡 Reliable in high-frequency and RF designs.

⚙️ Advanced equipment ensures lasting precision.

99.8% First-Pass Yield

🔒 High consistency and reliability in production.

✅ Industry-leading quality standards maintained.

🛠 Reduced rework through precise process control.

🏅 Zero-defect assemblies for customer trust.

ISO 9001 & RoHS Compliant

📋 Fully compliant with global quality standards.

🌍 Guaranteed safety and environmental compliance.

♻️ Sustainable production aligned with RoHS.

🔧 Certified systems ensuring continuous improvement.

Assembly Process

Our end-to-end assembly process covers every stage — from incoming inspection and parts preparation, to sub-assembly, full product integration, rigorous testing, and final delivery. This ensures precision, quality, and traceability from start to finish.

Incoming Inspection

Quality check for all materials and components.

Material Preparation

Organizing mechanical and electronic parts for assembly.

Sub-Assembly

Building functional modules with precision and reliability.

System Assembly

Integrating all modules into complete products.

Testing & Validation

Verifying full performance and long-term reliability.

Packaging & Delivery

Safe packing and global delivery to customers.

Assembly Capabilities

From inspection to integration, our assembly process ensures precision, flexibility, and reliability at every stage.

Incoming Inspection

- Quality verification for all incoming materials.

- Ensures parts meet specifications.

- Prevents defects from the source.

Material Preparation

- Organizing mechanical and electronic parts.

- Pre-assembly kitting for efficient workflow.

- Reduces assembly time and mix-ups.

Sub-Assembly

- Pre-build functional modules.

- Integrates plastics, wiring, and electronics.

- Improves modular reliability.

Final Product Assembly

- Combining modules into finished products.

- Ensures mechanical precision and stability.

- Supports both small and large-scale runs.

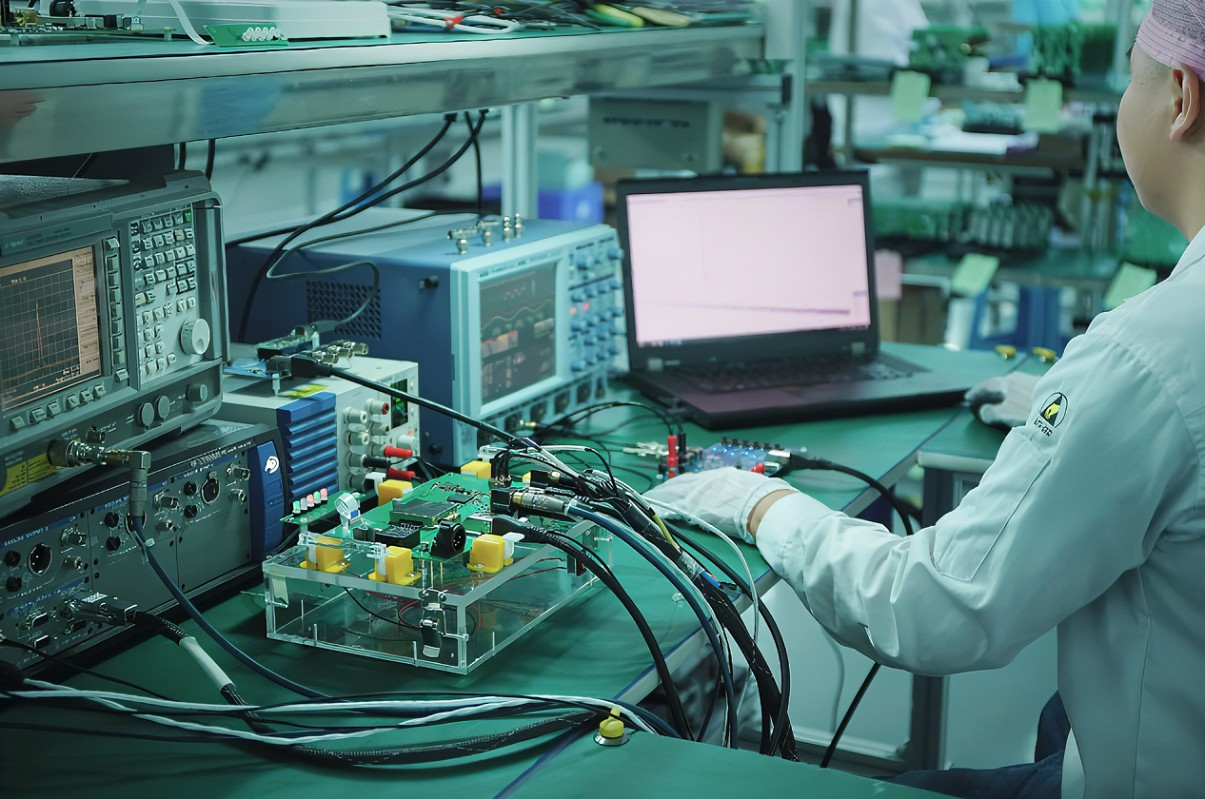

Testing & Validation

- Functional & reliability verification.

- Environmental and aging tests.

- Zero-defect assurance before shipment.

Packing & Shipping

- Anti-static and protective packaging.

- Full traceability and documentation.

- Global delivery with on-time tracking.

Quality & Standards

End-to-end quality management for complete product assembly — from incoming control to final testing, compliance, and full traceability.

- Functional test (EOL / end-of-line)

- Reliability & environmental tests (temperature, humidity, vibration, drop)

- Safety tests (hipot, ground continuity, insulation)

- Burn-in / stress screening

- Functional sub-assembly verification (modules & wiring)

- EMC pre-compliance (as required)

- Torque & force management for fasteners and press-fit parts

- Poka-Yoke (mistake-proofing) & guided work instructions (SOP)

- ESD protection & handling controls

- Process Control Plan & change management (ECN)

- Tooling & fixture calibration schedule

- Incoming inspection (AQL) & First Article Inspection (FAI)

- ISO 9001 quality management

- CE / UL conformity (as applicable)

- RoHS / REACH compliance

- Safety & EMC standards (IEC/EN)

- Industry-specific: ISO 13485 / IATF 16949 (optional per project)

- Ingress protection & durability (IP / life-cycle, when required)

- QR code & serial number tracking per unit

- MES data & test reports (COC/COA)

- Batch/lot records & component traceability

- Process parameter logging & change history

- Device history record (DHR) archiving

- Customer audits & third-party inspection support

Explore Our Product Assembly Journey

Discover our assembly site from material preparation to final product shipment. Each stage showcases our focus on

precision, efficiency, and quality control.

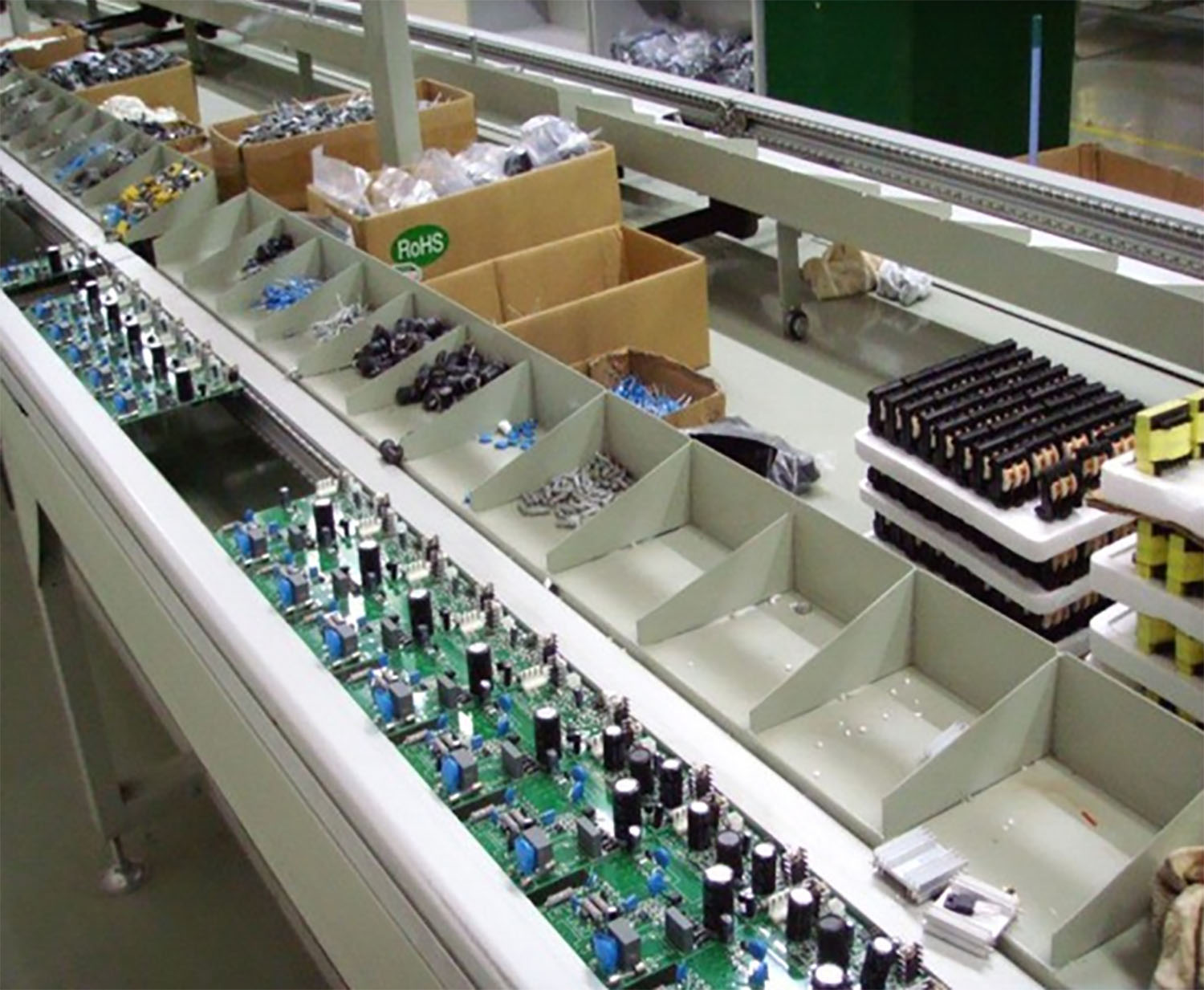

Workshop Overview & Line Layout

Line-side Kitting & ESD Workcells

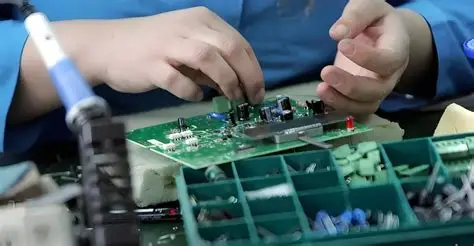

Precision Hand Assembly & Tools

Labeling, Kitting & Pre-pack

Get Your Quote Now

Send us your project details — quantity, delivery date, and BOM/design files — and we’ll get back within 24 hours.