Medical Electronic Devices

Medical Electronic Equipment

CINDY Mould provides precision solutions for medical electronic devices — covering plastic injection molding, metal insert overmolding, PCB assembly, and system integration.

Our cleanroom production and tight-tolerance assembly ensure each component meets strict standards of safety, durability, and biocompatibility.

We apply mold-flow simulation, CNC machining, and reliability testing under ISO 13485 and FDA requirements to guarantee stable performance.

From prototypes to mass production, CINDY Mould delivers one-stop medical manufacturing solutions that meet CE and RoHS compliance.

Our Capabilities in Medical Electronics Manufacturing

From precision plastic injection molding to PCB assembly and complete device integration, we provide one-stop manufacturing solutions for medical electronic devices with reliability, safety, and quality assurance.

Plastic + PCB Integration

- Seamless integration of plastic housings and PCB assemblies

- Precision fit ensures structural stability and electronic reliability

- Optimized for medical device enclosures and control modules

- Streamlined supply chain for cost and time efficiency

Custom Assembly Solutions

- Tailored injection molding for complex medical housings

- Flexible assembly and sub-assembly for medical electronics

- Supports prototype development and mass production

- Ideal for healthcare devices, monitoring units, and portable instruments

Tooling & Engineering Support

- In-house mold design and fabrication for precision components

- Control wall thickness, ventilation, and heat dissipation

- Advanced DFM (Design for Manufacturability) engineering

- Ensures stability and repeatability for high-precision medical parts

Testing & Validation

- Comprehensive electrical and mechanical reliability testing

- Life cycle, vibration, and durability validation for medical devices

- Compliance with CE, FCC, and UL standards

- Traceable quality documentation and verification reports

Production Scalability

- From low-volume prototypes to high-volume production

- Automated SMT and assembly lines ensure consistency

- Flexible capacity for urgent delivery or volume expansion

- Lean manufacturing for cost-efficient medical electronics

Customer & Technical Support

- Collaborative R&D and design support for client projects

- Transparent project management and progress updates

- After-sales technical service and continuous improvement

- Partnership-based approach for long-term medical OEM cooperation

Product Showcase

Explore our representative medical electronic components —

from transparent housings to miniature modules — designed to meet healthcare device needs.

Thermometer housing

Blood pressure monitor housing

Finger pulse oximeter housing

Smart bracelet case

Oximeter housing

Blood glucose meter housing

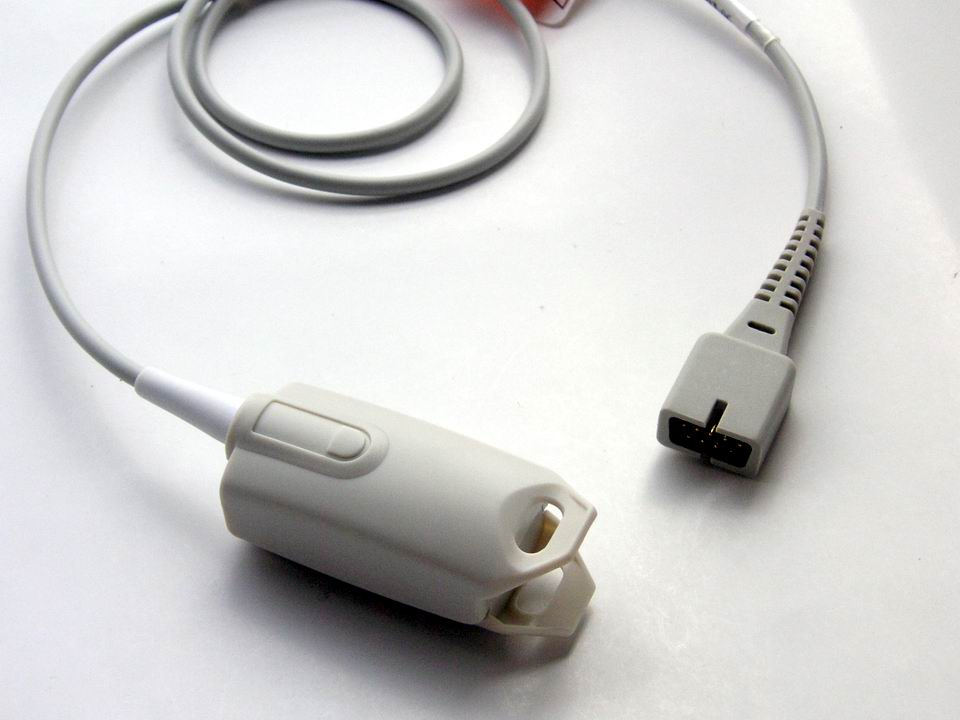

Finger clip oximeter

Infrared Thermometer

Finger pulse oximeter

Defibrillator

Pulse Oximeter

Digital Blood Pressure Monitor

Application Scenarios

Explore the applications of our medical electronics in different scenarios and provide solutions for various medical needs.

Home Care Medical Electronics

Small medical electronics offer convenient, accurate home health solutions for easy monitoring and management of key health indicators.

🩸 Blood Glucose Monitoring: Compact and easy meters for quick fingertip testing.

❤️ Vital Sign Tracking: Mini oximeters track SpO₂ and heart rate in real time.

📊 Health Data Logging: Syncs with mobile apps for automatic trend recording.

🔋 Low Power Design: Long-lasting, safe, and reliable for daily home use.

🧩 OEM/ODM Support: Custom housings, PCB, and assembly for home care devices.

Outdoor First Aid Medical Electronics

Compact medical electronic devices for outdoor safety — fast, portable, and reliable for on-site health checks and emergency response.

🩹 Wound & Vital Check: Mini sensors detect basic vital signs or wound status instantly.

🧰 Compact & Portable: Fits easily in small first-aid kits for hiking or travel.

⚡ Rapid Response: One-button operation delivers health data in seconds.

🔋 Durable & Low Power: Long battery life ensures reliable use in remote areas.

🧩 OEM/ODM Options: Custom design for portable first-aid kits and emergency medical devices.

Personal Health Management

Compact wearable medical electronics enable continuous health tracking, supporting proactive daily wellness.

❤️ Real-Time Tracking: Smart bands monitor heart rate, sleep, and activity.

📱 App Data Sync: Connects to mobile apps for trend charts and reports.

🔋 Long Battery Life: 24/7 operation with optimized low-power design.

🧠 Smart Alerts: Notifications for irregular heart rate or inactivity.

🧩 OEM/ODM Support: Custom design, PCB assembly, and full device integration.

Medical Electronics Manufacturing Capabilities

CINDY Mould supports medical electronics projects through precision tooling, controlled production processes, and ESD-safe electronic assembly. We focus on manufacturing execution and process reliability — not finished medical devices.

Injection Molding for Medical Electronics

Precision plastic housings and structural components

We manufacture precision plastic housings in a standard injection molding workshop with controlled production processes. Through DFM-driven mold design and tooling optimization, we ensure dimensional stability, material consistency, and reliable quality suitable for medical electronics assembly.

ESD-Safe PCBA Assembly

Stable electronic subassembly processes

PCBA assembly is performed on ESD-protected production lines with custom fixtures for accurate positioning. Integrated electrical and functional checks support consistent yields and compliance with CE and RoHS requirements.

Assembly & Process Validation

Verification and manufacturing control

We support mechanical assembly, functional verification, and process documentation under controlled conditions. Standardized inspection steps help ensure stable quality from pilot builds through volume production.

Quality & Compliance System

Our medical electronics manufacturing follows international quality systems and strict process controls—ensuring safety, reliability, and full traceability from material selection to final shipment.

ISO 13485 Certified

Certified QMS for medical device manufacturing

Consistent process & document control

Regular audits for continual improvement

Process Control & Traceability

End-to-end monitoring from molding to assembly

Batch records enable full traceability

Real-time data ensures quality stability

Material Compliance

Materials tested under ISO 10993 & RoHS

Safe for medical-grade contact

Validation reports traceable by batch

ESD & Cleanroom Controls

Class 10K cleanroom for sensitive builds

ESD-protected zones prevent discharge

Routine audits maintain environment

Reliability Testing

100% in-process inspection & validation

Electrical / mechanical / life-cycle tests

Ensures long-term performance stability

CE / FCC / RoHS Compliance

Certified for international markets

Third-party conformity verification

Ready for global export & legal compliance

Partner with CINDY Mould for Your Next Medical Electronics Project

From concept validation to mass production,

we provide precision, compliance, and reliability at every stage of manufacturing.