Industrial Controller Components

& Assembly Solutions

Industrial Controller

As a trusted partner in industrial automation, CINDY Mould provides end-to-end manufacturing solutions specifically for high-performance controller applications. Our integrated services cover custom enclosure molding, precision PCB assembly, seamless module integration, and rigorous final system testing. We are dedicated to delivering high-reliability products built to perform in harsh industrial environments, ensuring long-term stability and extended service life.

Leveraging expertise in flame-retardant materials, waterproof sealing (IP65/IP66/IP67), and metal-insert overmolding, we engineer durable housings and precise electronic modules that comply with strict EMC/EMI, safety (UL, CE, RoHS), and environmental standards. Every unit undergoes comprehensive validation, including functional testing, electrical safety checks, and environmental stress screening, guaranteeing performance and compliance.

Our engineering and R&D teams collaborate closely with clients to streamline development cycles through rapid prototyping, CNC machining, and mold flow analysis, enabling faster iteration and a smoother transition from concept to mass production.

From low-volume pilot runs to full-scale production, our flexible OEM/ODM services help manufacturers mitigate supply chain risks, reduce total cost of ownership, and accelerate time-to-market without compromising on quality. Partner with us to build the robust, reliable industrial controllers your market demands.

Our Services – Modular Capabilities for Industrial Controllers

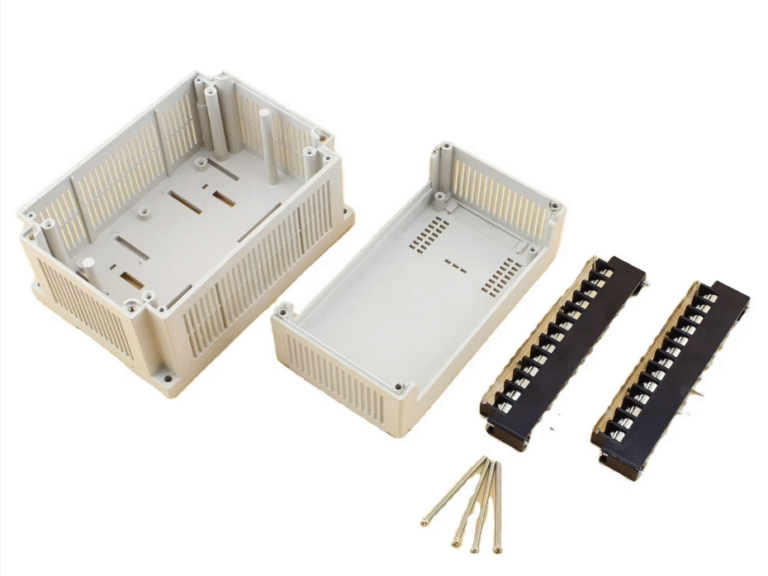

Custom Enclosure Fabrication

We provide fully customized enclosures for industrial controllers, including plastic, metal, and hybrid materials. Our services cover housings, mechanical brackets, buttons, and connectors designed to meet your project-specific requirements. We support complex geometries, metal-insert overmolding, precision machining, and surface treatments, ensuring every enclosure is functional, durable, and ready for assembly.

Benefits:

Tailored enclosures for client-specific control modules

Wide range of materials: plastic, metal, and hybrid solutions

High precision and durability for reliable system integration

Suitable for both prototyping and large-scale production

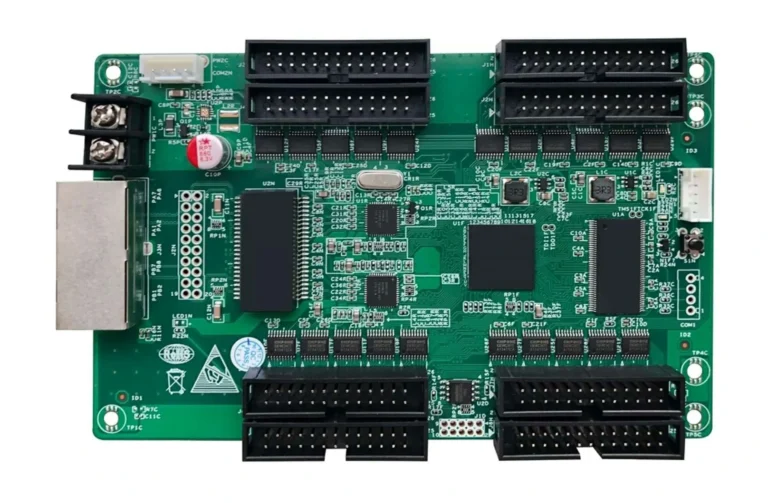

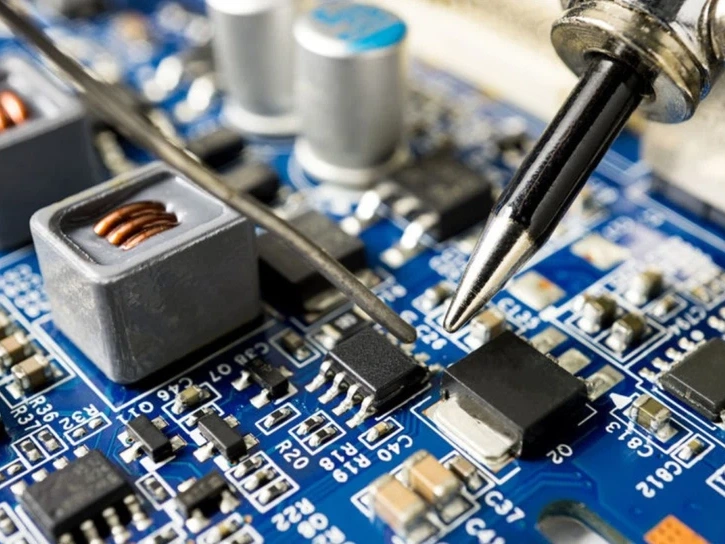

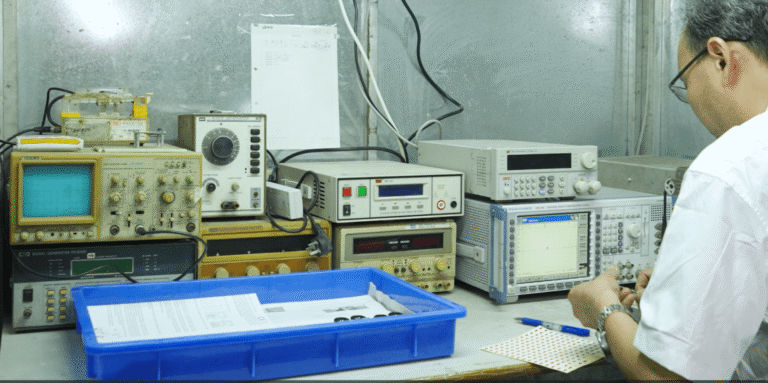

PCBA Assembly

We assemble client-provided PCBs or full electronic modules for industrial controllers, including surface-mount (SMT) and through-hole (THT) component placement. Functional testing and inspection are performed to guarantee reliable operation and compliance with industry standards.

Benefits:

Accurate and reliable PCB assembly for control systems

Reduced defects through automated and manual testing

Scalable from low-volume prototypes to high-volume production

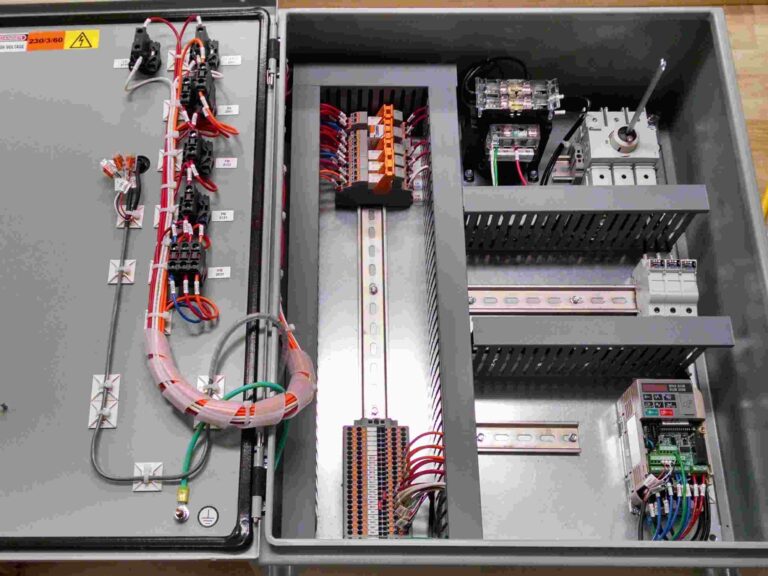

System Integration

We integrate PCB assemblies, terminal blocks, displays, and molded components into fully functional industrial controller units. This turnkey service ensures all mechanical and electrical parts work seamlessly together, providing clients with ready-to-use control modules.

Benefits:

One-stop assembly solution from parts to complete modules

Ensures compatibility and operational reliability

Simplifies logistics and reduces assembly complexity for clients

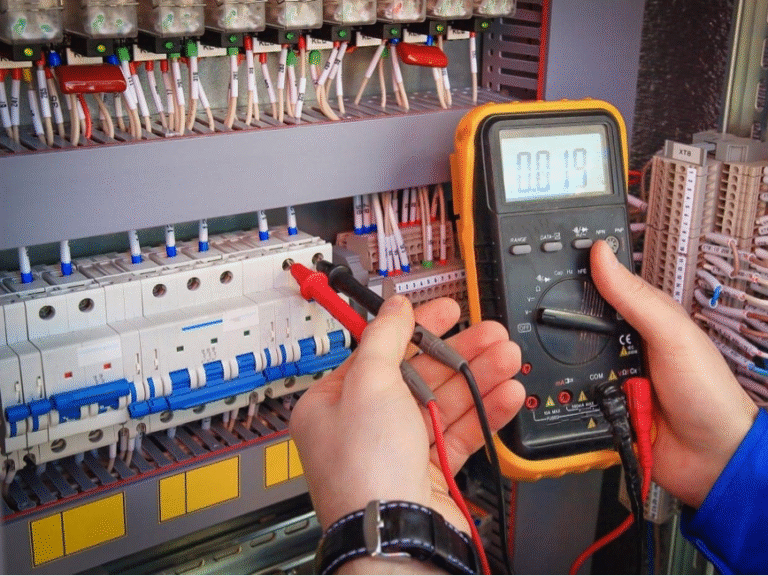

Quality Assurance

Our rigorous quality assurance processes ensure every assembled industrial controller meets the highest standards of performance and reliability. Services include electrical testing, functional checks, durability and environmental stress tests, and in-process inspections. All work complies with international standards such as ISO9001 and RoHS.

Benefits:

Guarantees reliable operation in industrial environments

Minimizes failure rates and maintenance issues

Provides clients with confidence in end-product quality

Industry Requirements We Meet

Compliance & Reliability

Technical Features

Our Successful Projects

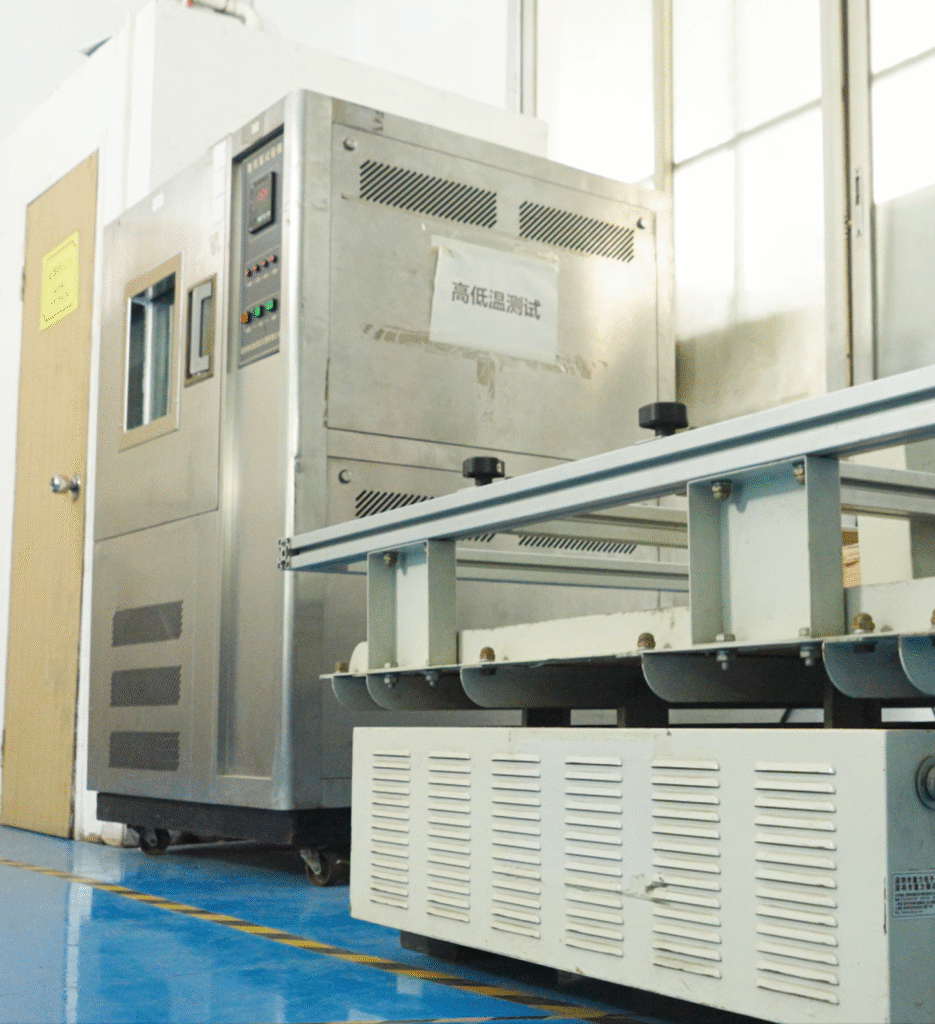

Case 1: Custom Industrial Temperature Controller Module

Client Background: An European industrial equipment manufacturer

Challenge: The client required a control module capable of continuous operation in high-temperature environments. The enclosure needed to be dust- and water-proof (IP66), and the internal PCBA had to be precisely assembled to ensure long-term stability.

Our Solution:

Designed and customized a metal + plastic hybrid enclosure, balancing heat dissipation and protection

Precision injection molding and assembly with ±0.05mm tolerance to ensure correct placement of electronic components

Conducted comprehensive functional testing, electrical testing, and durability verification to meet international standards

Integrated DIN rail mounting and client-specified interfaces for seamless integration into equipment

Result:

The module operated stably in continuous 80℃ environments for over one year

High client satisfaction, with repeat orders for custom assembly in subsequent projects

Temperature and Humidity Chamber

Case 2: Industrial Automation Control Cabinet Module

Client Background: A North American automation equipment company

Challenge: The client wanted to accelerate the assembly of internal control cabinet modules, reduce costs, and maintain high protection (IP65) and reliable electrical connections.

Our Solution:

Provided a comprehensive one-stop assembly service, covering PCB assembly, terminal blocks, displays, and enclosure integration, eliminating multiple vendor coordination

Immediate response for design and production of custom enclosures and PCBs to shorten development cycles

Sent prototype samples via international express shipping for fast client confirmation

Conducted functional inspection, electrical safety testing, and EMC interference testing to guarantee reliability

Designed modules for scalability and easy future upgrades, further reducing long-term production time and effort

Result:

Module delivery time reduced by 30%, significantly improving production efficiency and saving costs

Clients benefited from streamlined assembly, fast sample confirmation, and shorter time-to-market

Industrial One-Stop Assembly

Future Outlook

The industrial control and automation industry is evolving rapidly, driven by the rise of smart manufacturing, Industry 4.0, and the demand for more efficient, reliable, and modular control solutions.

In the coming years, industrial control modules are expected to:

Embrace greater modularity: allowing easier maintenance, upgrades, and customization for diverse applications

Integrate advanced electronics and IoT connectivity: enabling real-time monitoring, predictive maintenance, and data-driven optimization

Enhance reliability under extreme conditions: with materials and designs that withstand high temperatures, dust, moisture, and vibration

Accelerate production cycles: through one-stop assembly, rapid prototyping, and streamlined supply chains

Comply with evolving international standards: ensuring safety, sustainability, and global market compatibility

At CINDY Mould, we are committed to staying ahead of these trends, delivering high-precision, customizable, and reliable industrial control modules that help our clients achieve faster time-to-market, lower costs, and superior operational efficiency.