Product Enclosure Manufacturing

Custom plastic & hybrid enclosures from mold design to finished assembly — faster DFM decisions, lower total cost.

Our Manufacturing Processes

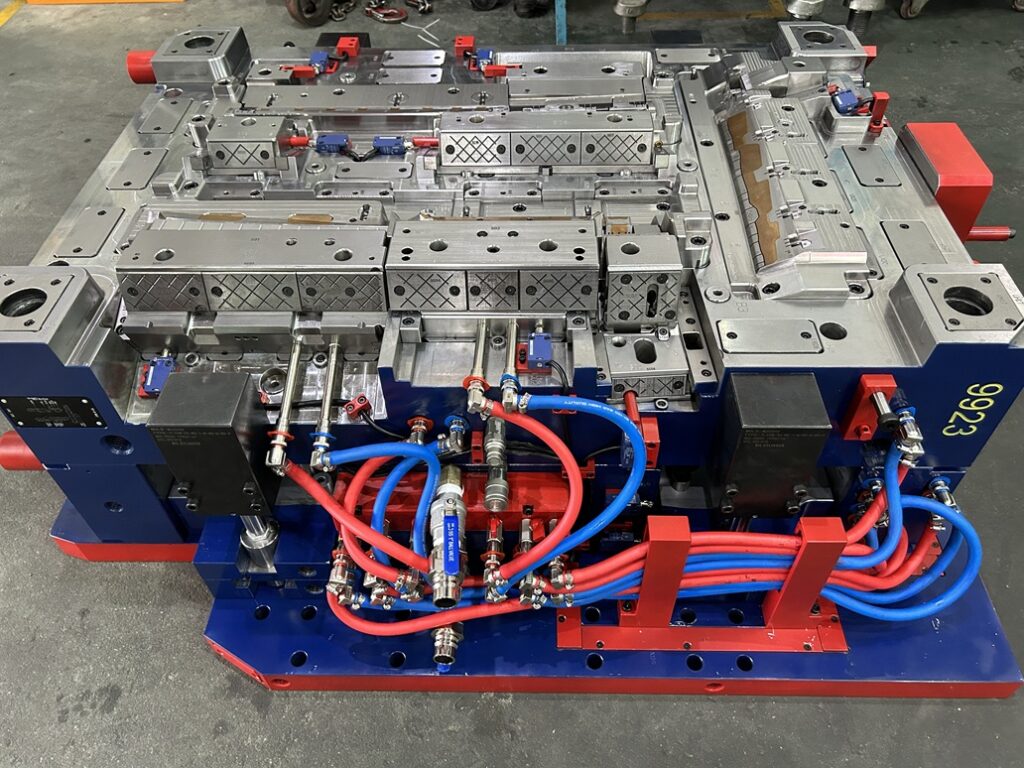

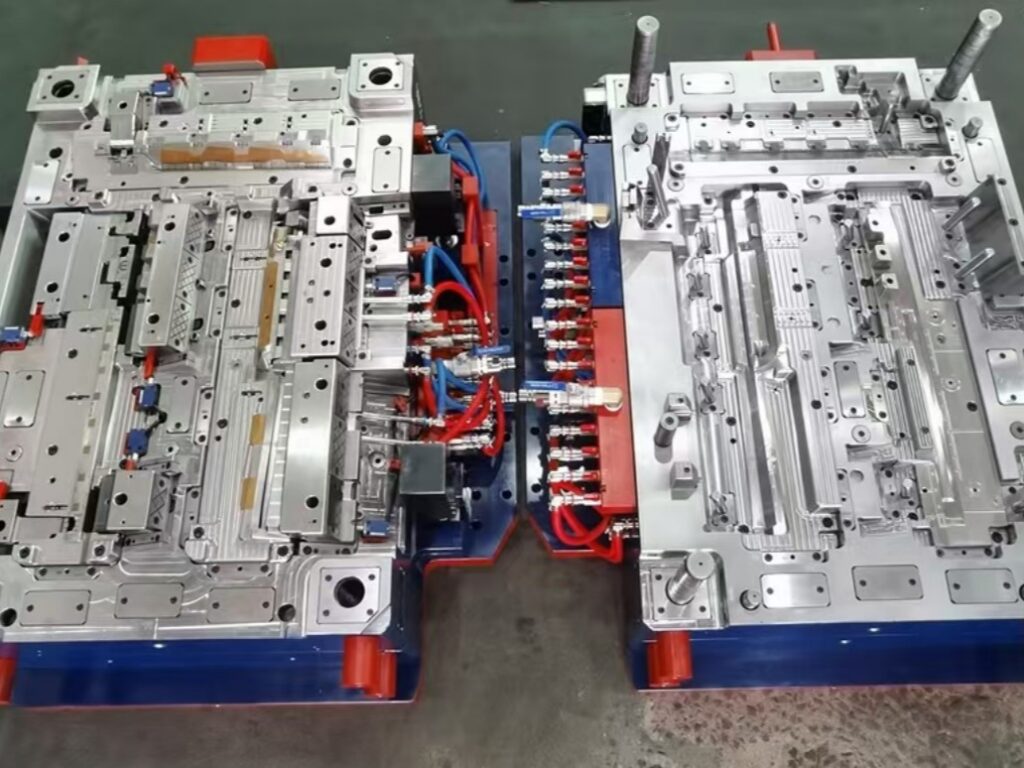

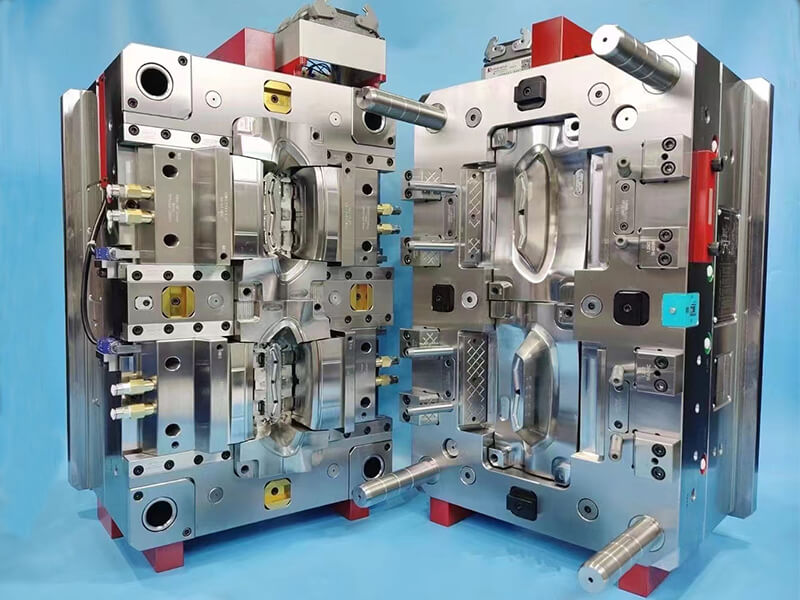

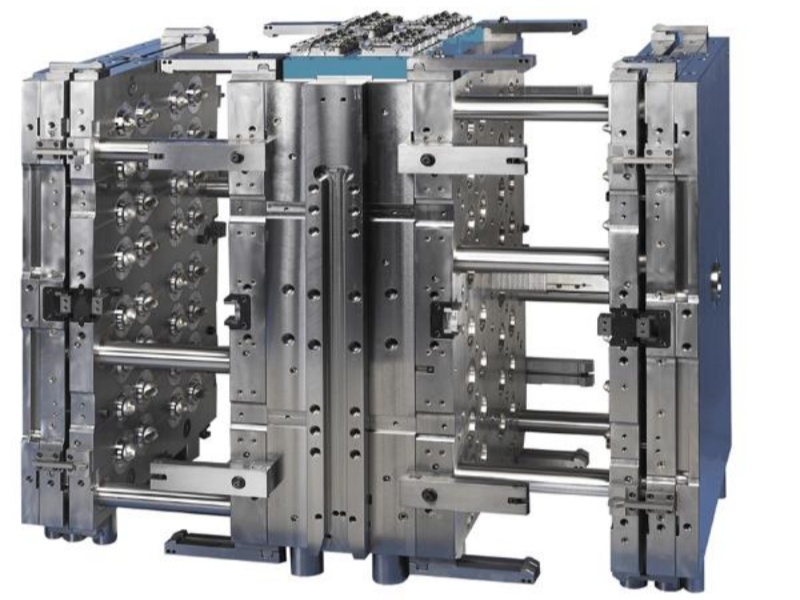

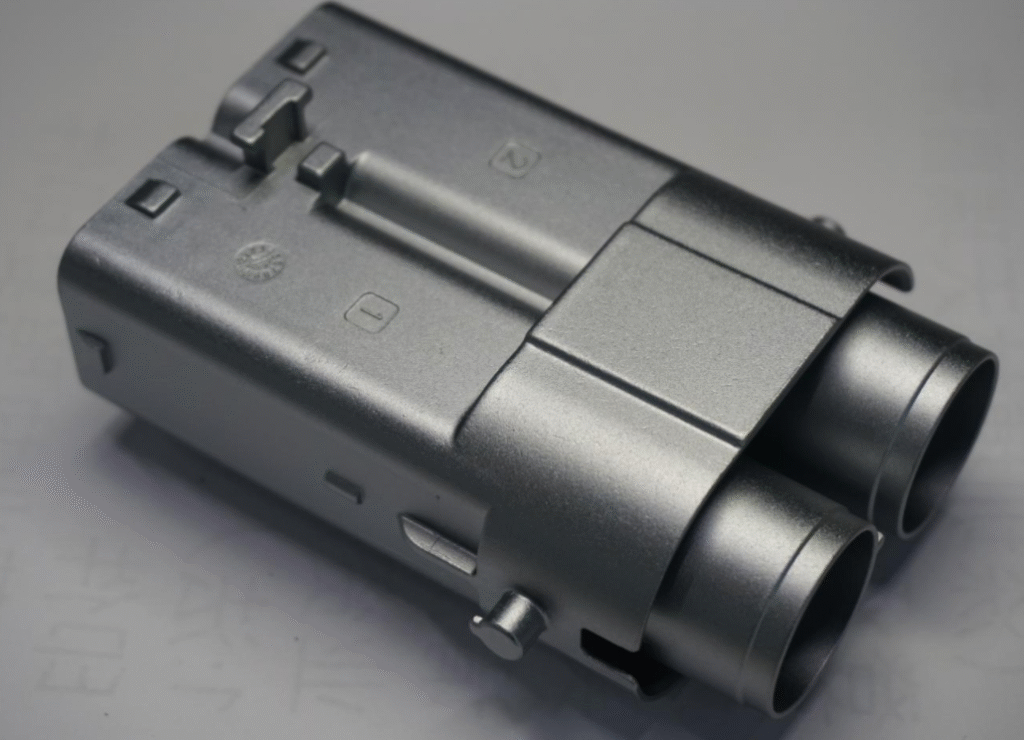

Injection Molding

We provide custom plastic housings for electronics, hand-held devices, appliances, and more. Our injection molding capabilities include single-shot, two-shot, overmolding, and transparent parts production.

Common Materials

- ABS, PC, PC/ABS, PA, PBT, TPE…

Design-to-Production Process

- Customer provides CAD files & requirements

- DFM (Design for Manufacturing) analysis

- Moldflow simulation to optimize flow, venting, and shrinkage

- Mold fabrication & trial runs (T1/T2)

- Sample verification & mass production

Advantages

- Precise dimensional control

- Complex structures achievable

- Cost-effective for mass production

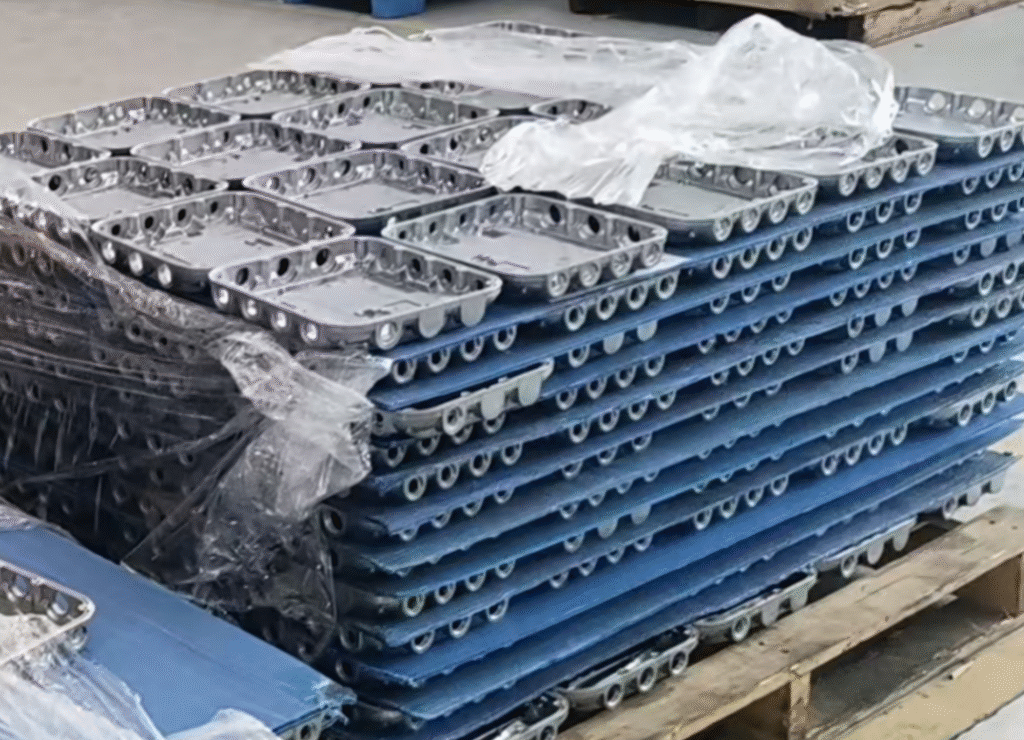

CINDY MOULD is a proud subsidiary of JIN YI MOULD. All our injection-molded housings are manufactured by JIN YI, located in Guangdong, China. With two state-of-the-art mold and injection molding facilities covering over 30,000 square meters,

JIN YI provides us with robust technical expertise and powerful production capacity.

Click the button below to learn more.

Die Casting and Metal Stamping

In addition to producing high-quality plastic housings through injection molding, we also offer a comprehensive range of metal housing solutions to meet your product needs. Our capabilities include die casting and metal stamping, enabling us to manufacture durable and precision-engineered enclosures from materials such as aluminum alloy, zinc alloy, and more. Whether you require lightweight yet strong aluminum casings, corrosion-resistant zinc alloy parts, or custom-fabricated sheet metal components, our advanced equipment and skilled engineering team can bring your designs to life with outstanding accuracy and finish.

Die Casting

Metal housings with excellent strength and thermal conductivity, ideal for industrial and mechanical applications.

Materials: Aluminum alloy, Zinc alloy, Magnesium alloy…

Thin walls with high precision

Requires surface finishing after casting

Metal Stamping

Fast, cost-effective process for producing metal panels, brackets, and small enclosures.

Materials: Stainless steel, Aluminum, Copper

High-volume production at low cost

Surface Finishing & Appearance

We provide a full spectrum of surface finishing options to elevate both the look and performance of your products. From decorative effects to protective coatings, our advanced finishing techniques deliver durability, precision, and premium aesthetics.

Our Engineering Support

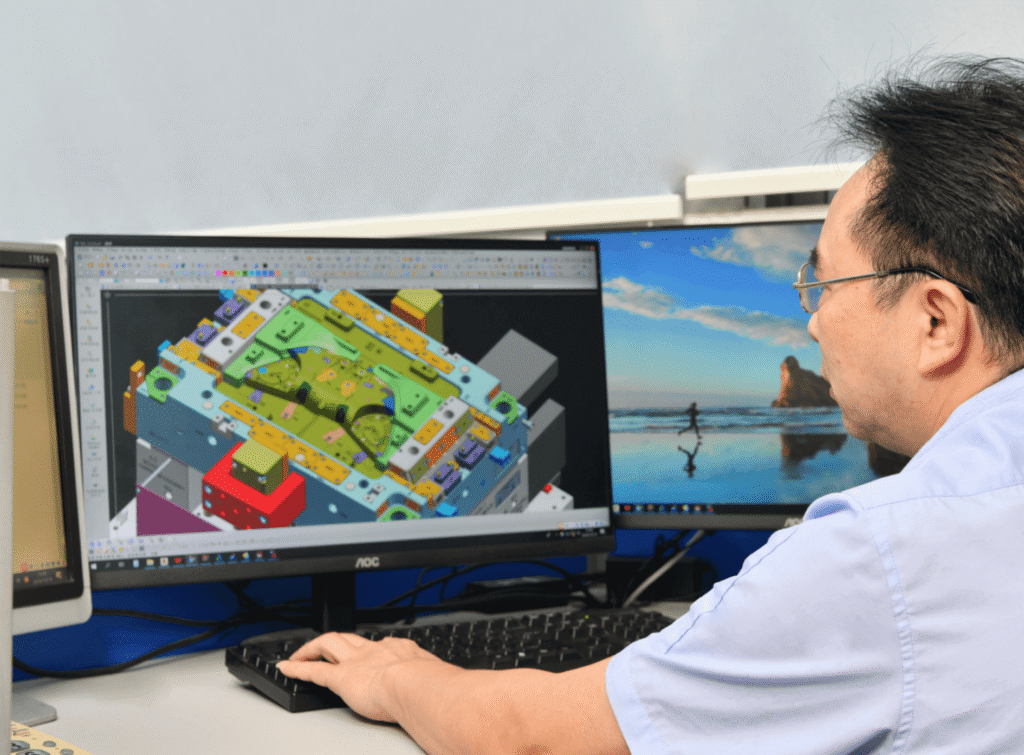

Mold Design

From design through to full-scale production, our engineering team provides end-to-end technical support, maximizing efficiency and ensuring manufacturability in both injection molding and metal housing production, including die casting and metal stamping. Our services include professional evaluations such as Design for Manufacturing (DFM) analysis, Moldflow simulation, tolerance and warpage control, material selection for plastic and metal parts, and structural optimization, along with prototype tooling and rapid prototyping to accelerate time-to-market for both plastic and metal enclosures.

Our technical capabilities also cover:

• Mold design, CNC precision machining, and tooling for plastic and metal housings

• Quality control and inspection systems to ensure dimensional accuracy and surface finish

• PCBA integration and assembly feasibility validation for complex enclosures

• Production cycle time and cost optimization for injection molded and die-cast components

Engineering Services

One-Stop Service Advantages

From Design to Delivery: Our Complete One-Stop Manufacturing Process

FAQ

What services do you offer?

We provide one-stop manufacturing solutions, including injection mold making, plastic injection molding, PCBA assembly, and final product assembly.

What is your (MOQ) for plastic parts?

Our MOQ for plastic injection molding is usually 500 pieces, but we can discuss lower quantities for prototypes or special projects.

Do you provide design support before manufacturing?

Yes, our engineering team offers DFM (Design for Manufacturing) analysis, moldflow simulation, material selection advice, and structure optimization to ensure manufacturability and cost efficiency.

Can you handle both the enclosure and internal PCBA assembly?

Absolutely. We offer one-stop service from enclosure manufacturing to PCBA integration and final product assembly, minimizing the need for multiple suppliers.

What surface finishing options do you provide?

Our capabilities include painting, powder coating, screen/pad printing, laser engraving, electroplating, anodizing, polishing, brushing, texturing (VDI, MT, SPI), and EMI shielding coatings.

Do you support metal housings in addition to plastic enclosures?

Yes, we manufacture die-cast housings in aluminum (ADC12, A380) and zinc alloys, as well as stamped metal parts from stainless steel, aluminum, and copper.

Do you ship internationally?

Yes, we export products worldwide, with customers in the US, Germany, Brazil, Japan, Slovenia, and more. We can arrange shipping by air, sea, or express courier.

Can you customize enclosures to fit our PCBA and mechanical structure?

Yes, we validate assembly feasibility with PCBA and internal mechanical parts to ensure precise fit and functionality.

How do you control quality during production?

We implement strict quality control systems, including CNC precision machining for molds, in-process inspections, and final product testing to ensure consistent quality and traceability.

What is your typical lead time for mold making and production?

Lead times vary depending on complexity, but we also provide rapid prototyping and trial molds to accelerate time-to-market.

Ready to Build Your Product?

Share your drawing and requirements — our team will provide DFM feedback and a quote quickly.