PRECISION PCB TESTING SERVICES

Ensuring quality, reliability, and compliance with

inaustry standard, for every board we test.

OUR CORE TESTING CAPABILITIES

PCB Testing Capabilities

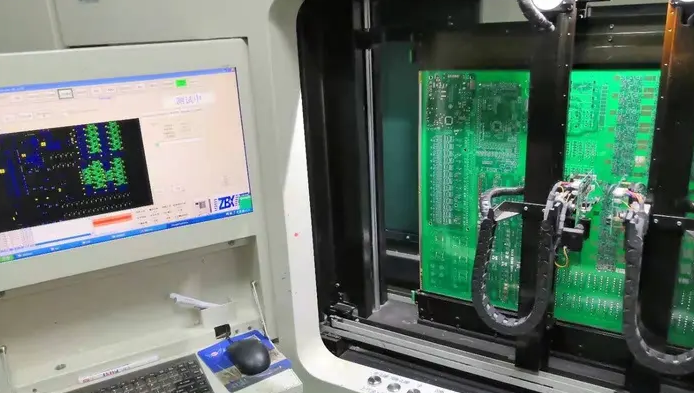

AOI Automated Optical Inspection

High-speed defect detection with precision cameras.

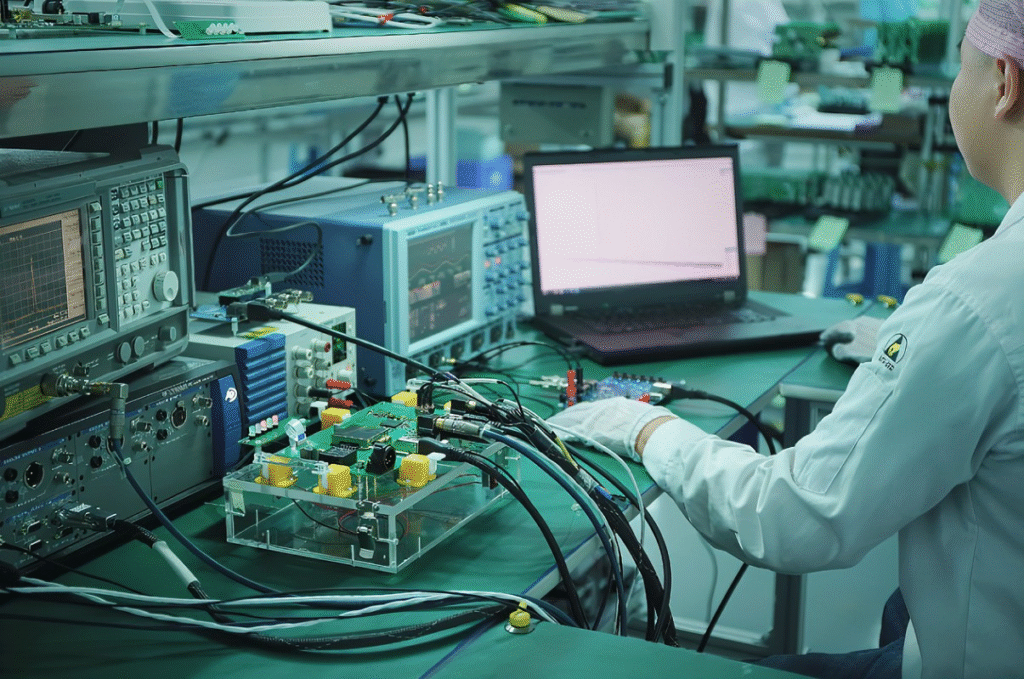

Functional Testing

Simulating real-world operating conditions.

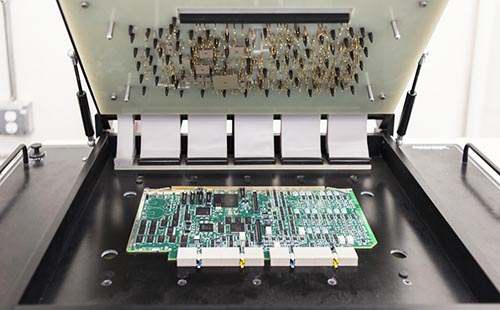

ICT In-Circuit Testing

Accurate electrical testing for assembled boards.

Environmental Stress Testing

Verifying reliability under extreme conditions.

PCB Testing Process

Order Review

Check specs & requirements.

Sample Prep

Prepare boards & fixtures.

AOI Inspection

Detect solder & defects.

Electrical Test

Verify nets & values.

Functional Test

Ensure performance.

Final Delivery

Report & ship boards.

Detailed Testing Services

Automated Optical Inspection (AOI)

High-resolution imaging to detect solder joints, component alignment, and surface defects.

- Principle: Optical vision compares captured images with golden reference.

- Applications: Fine-pitch, HDI boards, BGA/QFN alignment.

- Capabilities: Resolution ≤ 5–10 µm; false-call rate < 0.1%.

- Client Benefits: Reduce rework & defects; faster feedback to process.

In-Circuit Testing (ICT)

Electrical verification of nets, values, orientation, and shorts/opens before final assembly.

- Principle: Probe matrix measures component values and continuity.

- Applications: Mass production with stable test coverage.

- Capabilities: Up to 2048 nodes; boundary-scan optional.

- Client Benefits: Catches early failures; stable quality at scale.

Functional Verification

Simulates real operating conditions to validate firmware, interfaces, and performance.

- Principle: Power-on, I/O simulation, interface loopback & load tests.

- Applications: MCU/FPGA boards, IoT devices, communication modules.

- Capabilities: USB/UART/CAN/Ethernet; programmable loads 0–10 A.

- Client Benefits: Ensures user-level functionality before shipment.

Environmental & Reliability Tests

Stress tests for durability under temperature, humidity, and vibration cycles.

- Principle: Accelerated aging by thermal/humidity or mechanical stress.

- Applications: Automotive, outdoor, industrial control electronics.

- Capabilities: −40 °C ~ +85 °C; 10–95 %RH; vibration per spec.

- Client Benefits: Predict field reliability; lower warranty risk.

Our Testing Advantages

Delivering precise, reliable results through advanced technology and expert know-how.

High Accuracy

AOI precision down to 5–10 µm, stable and repeatable results.

Comprehensive Coverage

Electrical, functional, and environmental tests across product stages.

Fast Turnaround

Streamlined workflow with same-day reporting for urgent projects.

Standards Compliance

IPC/J-STD/ISO aligned processes and traceable reports.

Experienced Engineers

Senior team with 10+ years in PCB & PCBA testing.

Custom Fixtures

Tailored ICT/functional jigs to match your board design.

Trusted by Leading Manufacturers

Validated results, traceable reports, and rapid turnaround trusted by global electronics teams.

- 99.2%First-Pass Yield in Pilot

- ≤ 10 µmAOI Detection Precision

- 24hSame-Day Reporting (urgent)

Same-day AOI/ICT reports let us fix process drift before it reached mass production.

Environmental stress testing replicated our field failures exactly. Warranty risk dropped sharply.

Fixtures and ICT coverage improved our FPY across multiple SKUs by over 15%.

Traceable reports and IPC-aligned process made customer audits straightforward and efficient.

BGA yield stabilized under aggressive takt time—highly recommended partner.

Professional, fast and consistent. Their feedback loop cut our RMAs by 70%.

Same-day AOI/ICT reports let us fix process drift before it reached mass production.

Environmental stress testing replicated our field failures exactly. Warranty risk dropped sharply.

Fixtures and ICT coverage improved our FPY across multiple SKUs by over 15%.

Traceable reports and IPC-aligned process made customer audits straightforward and efficient.

BGA yield stabilized under aggressive takt time—highly recommended partner.

Professional, fast and consistent. Their feedback loop cut our RMAs by 70%.

Ready to Enhance Your PCB Testing?

Same-day reporting for urgent projects, IPC/ISO-aligned processes, and traceable results.

Request a Quote