Professional Electronic Design for Your Project

Professional Team

10+ years in circuit design, board layout, and system integration.

Design Expertise

Custom PCB layout & circuit design tailored to your product.

Engineering Validation

DFM analysis, testing, and optimization from prototype to mass production.

Reliable Partner

ISO-compliant processes and dedicated team support from concept to delivery.

Our PCB Services

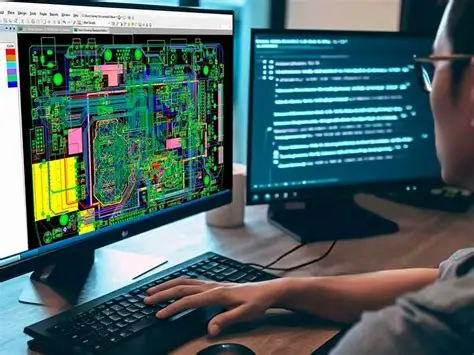

PCB Design

From schematic to layout — we support your product realization.

Support client-provided schematics or assist in refinement

Professional engineering support with rapid iteration and design validation

Ensure DFM compatibility for smooth production

Embedded firmware or sensor circuit integration (if applicable)

SMT Assembly

High-precision surface-mount assembly for prototypes and production.

Support both small-batch prototypes and mass production

Advanced SMT lines for fine-pitch ICs, BGAs, and other SMD components

Strict process control to ensure solder quality and placement accuracy

Component sourcing and procurement support for seamless assembly

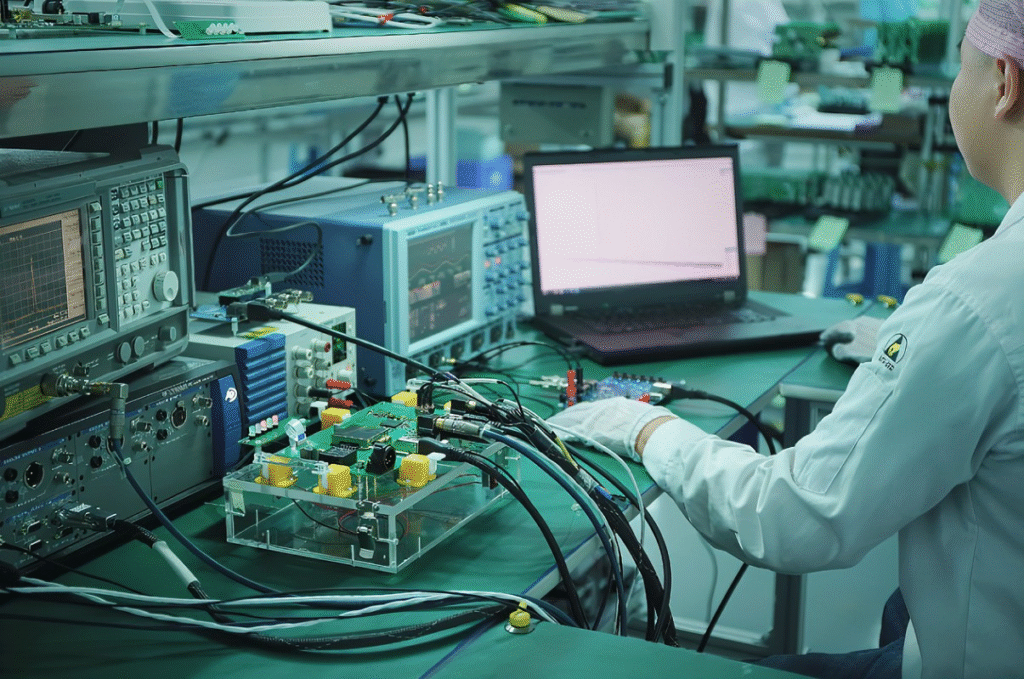

Testing Services

Comprehensive testing to ensure product reliability and functionality.

Functional testing for PCBA and integrated systems

Automated Optical Inspection (AOI) and In-Circuit Testing (ICT)

BGA/X-ray inspection and quality verification

Customized testing protocols to meet client specifications

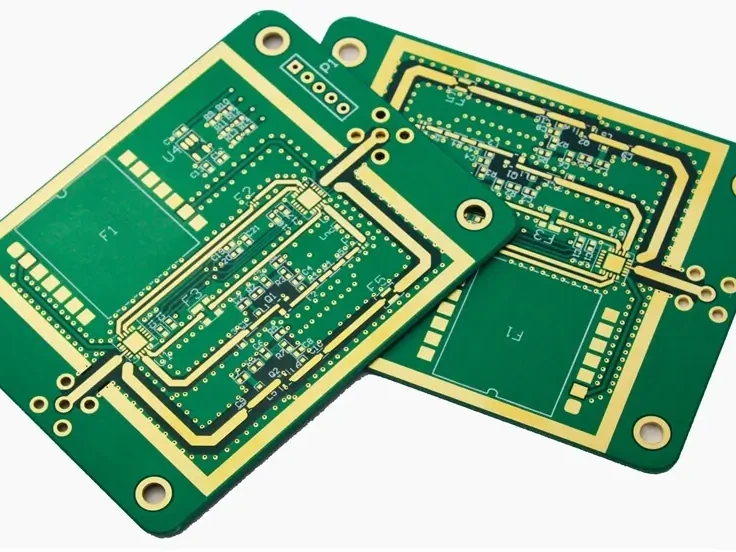

Fabrication Capabilities

Cindy Mould delivers versatile PCB solutions across multiple board types and materials, ensuring reliable performance for a variety of applications.

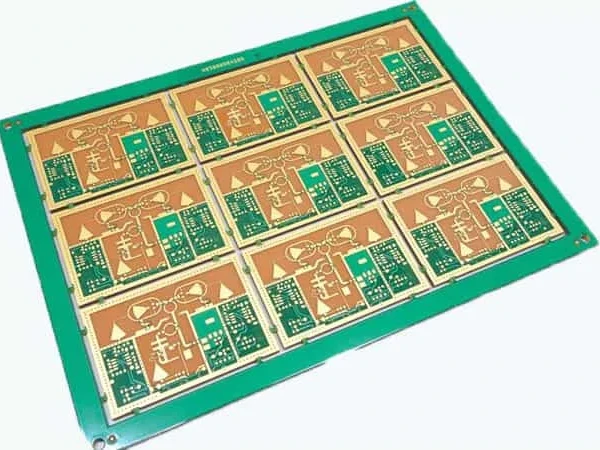

Rigid PCB

Standard rigid PCBs for general electronics, available in 1–32 layers. Reliable and versatile for most applications.

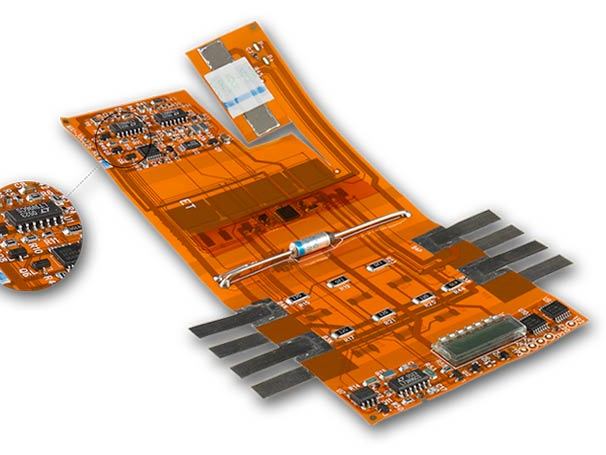

Flexible PCB

Bendable PCBs for compact and foldable devices. Ideal for wearables, IoT, and portable electronics.

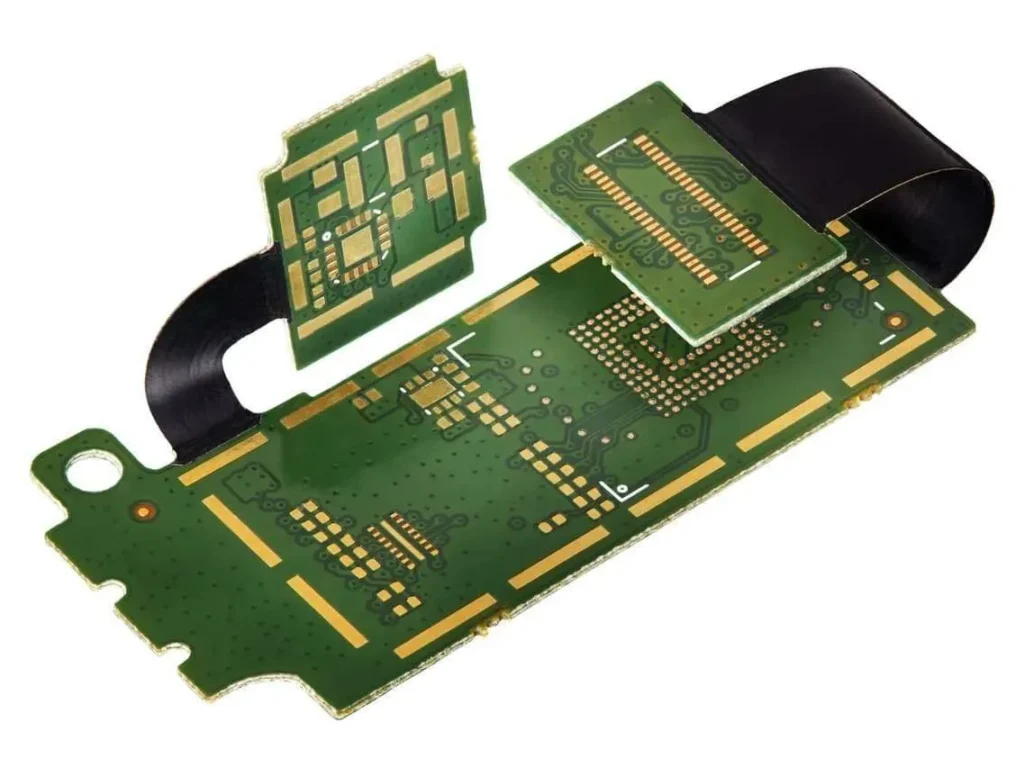

Rigid-Flex PCB

Combination of rigid and flexible layers for high-density, durable designs in complex products.

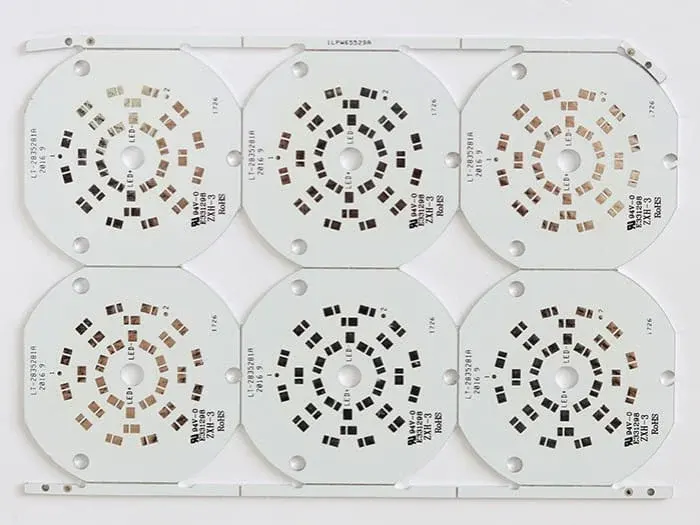

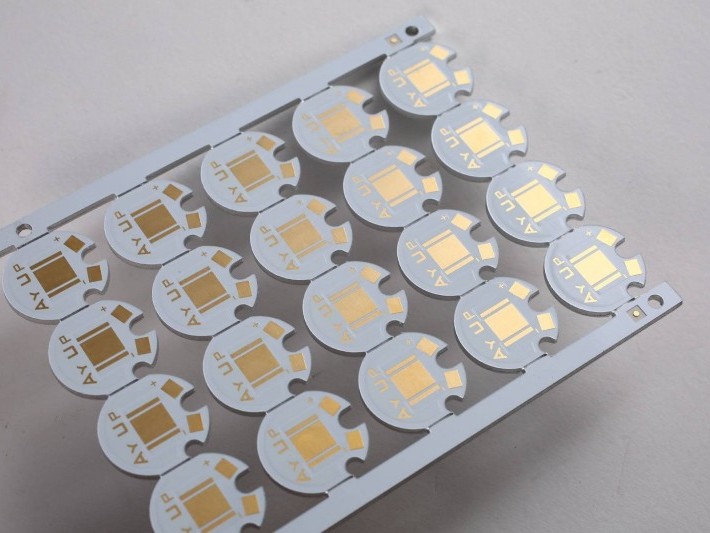

Aluminum PCB

Excellent thermal performance with 1–6 layer aluminum boards. Perfect for LED and power electronics.

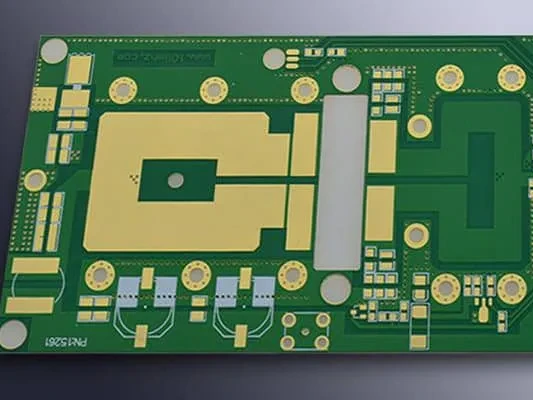

High Frequency PCB

Optimized for GHz-level signals using materials like Rogers and Taconic. Suitable for RF, 5G, and network devices.

High TG PCB

High-temperature PCBs ensuring stable operation under thermal stress. Used in automotive and industrial electronics.

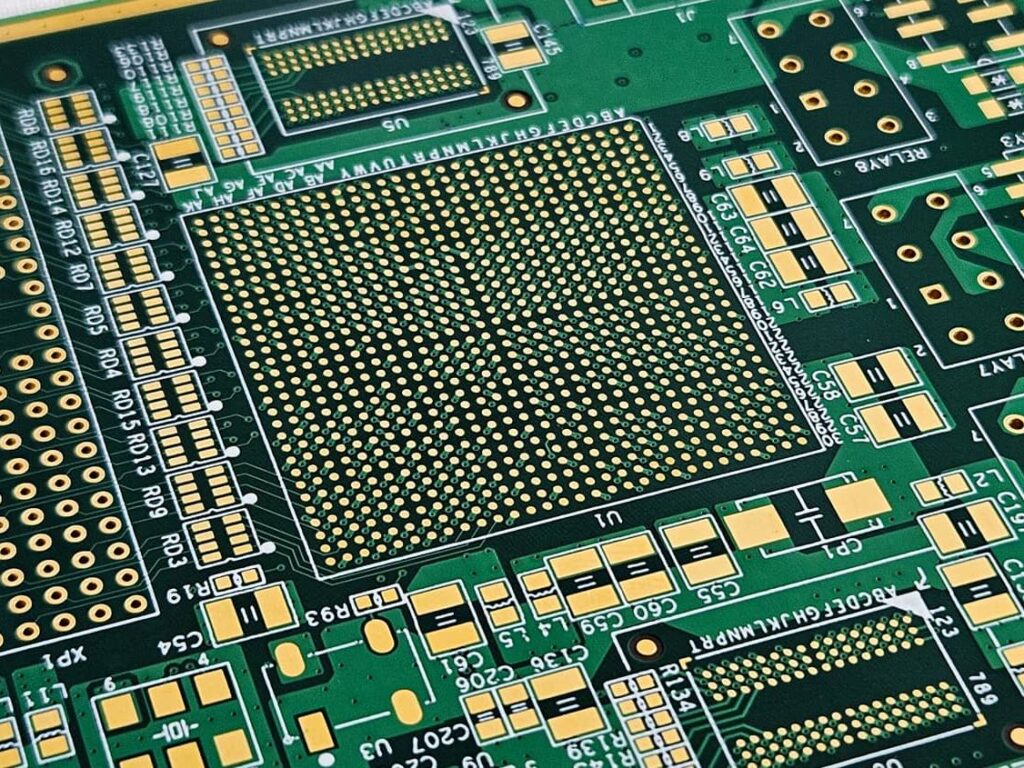

HDI PCB

High-density interconnect PCBs for compact, high-performance devices like smartphones and tablets.

Metal Core PCB

PCBs with metal substrates for superior heat dissipation and high-power applications.

Trusted by Our Clients

Cindy Mould as a reliable partner in PCB assembly and PCBA manufacturing, we are proud to be trusted by leading brands across industries. From prototype to mass production, our turnkey solutions ensure high-quality circuit boards, precise component placement, and rigorous testing at every stage. Our clients count on us for fast lead times, consistent quality, and professional service in every project.

Our Trusted Partners

Global Technology Partnerships Supporting Reliable Electronics Manufacturing

To ensure every project is built on a dependable foundation, we operate within a fully manufacturer-authorized supply chain covering a broad range of electronic components, including semiconductors, connectors, sensors, passive parts, power modules, and other essential hardware.

Our long-term partnerships span leading global technology brands, supporting stable sourcing for PCB manufacturing, PCB assembly, and full OEM/EMS production.

By integrating these trusted component ecosystems into our workflow, we provide consistent quality, full traceability, and reliable availability throughout the product lifecycle.

This approach allows our customers to streamline electronics sourcing, reduce procurement risks, and accelerate product development with components that meet international compliance and performance standards.

Whether you are building consumer electronics, industrial devices, smart-home products, automotive modules, or IoT hardware, our authorized global partner network ensures your project is supported by proven, high-quality technology from start to finish.