Custom Electronic Devices for Consumer and Professional Applications

Custom Electronics Solutions

At CINDY Mould, we partner with brands to transform custom electronic device concepts into market-ready products, covering both consumer and professional applications. From initial design support to full-scale production, we provide end-to-end manufacturing solutions that streamline development, simplify supply chains, and ensure high-quality outcomes.

Our team combines engineering expertise, advanced injection molding techniques, and electronics integration to produce devices that are durable, reliable, and visually refined. We specialize in precision molding, two-shot and insert molding, soft-touch finishes, high-density PCB integration, and complex component assembly, enabling products to meet strict performance, ergonomics, and reliability requirements.

With global component sourcing, rapid prototyping, and flexible production scaling, we help clients accelerate development cycles and confidently bring products to market. Each device undergoes rigorous functional, reliability, and compliance testing, ensuring adherence to standards such as FCC, CE, and RoHS.

Whether for small pilot runs or large-scale OEM/ODM production, we deliver tailored solutions that support innovation, reduce risk, and help your electronic devices stand out in a competitive market.

Detailed Capabilities

Design Support & Product Replication

We not only manufacture products, but also help transform customer-provided designs or existing samples into production-ready solutions. These services allow us to rapidly convert concepts or existing products into feasible, manufacturable designs, reducing development risks and accelerating time-to-market.

Reverse engineering: Disassemble, measure, and analyze existing products to create accurate digital models.

Data acquisition: Capture structure, dimensions, materials, and functionality for complete documentation.

Design optimization: Apply mold flow analysis, structural reinforcement, and process feasibility improvements.

Prototyping & validation: Produce rapid prototypes and perform functional testing to ensure the design meets expectations.

IP protection: Work strictly on customer-owned designs and products to protect intellectual property throughout the process.

Precision Injection Molding for Custom Electronics

We provide advanced injection molding solutions for custom electronic devices, producing housings that are both durable and visually refined.

Material support: ABS, PC, PC/ABS, TPE, and other engineering plastics.

Equipment range: Injection machines from 80 to 1600 tons to handle small and large components.

Advanced processes: Two-shot/multi-color molding, insert molding, and soft-touch overmolding.

Surface finishing: IML/IMF, NCVM metallic coating, high-gloss painting, and textured finishes.

Process optimization: Mold flow analysis and design recommendations to ensure accuracy, reduce defects, and improve efficiency.

PCB Fabrication & Component Procurement

Our end-to-end PCB services ensure high-density modules meet the performance and reliability standards required for custom electronic devices.

PCB fabrication: HDI and miniaturized PCBs for compact designs.

Component procurement: Global sourcing of high-quality electronic components for small and large production runs.

Supply chain assurance: Timely delivery of critical parts to support rapid prototyping and production.

Quality control: Inspection and testing of PCB assemblies to guarantee performance and compliance.

Integration support: Coordination with molding and assembly teams for seamless device integration.

Electronic Assembly & Device Integration

We provide complete assembly solutions, transforming PCB modules and components into fully functional custom electronic devices.

Assembly techniques: SMT/DIP placement, hand soldering, and complete device integration.

Module integration: Combine functional modules with housings to form ready-to-use devices.

Testing & reliability: Functional, environmental, and stress testing to ensure performance and durability.

Compliance standards: FCC, CE, RoHS, and other certifications as required.

Production support: Coordinated workflow from prototype to mass production.

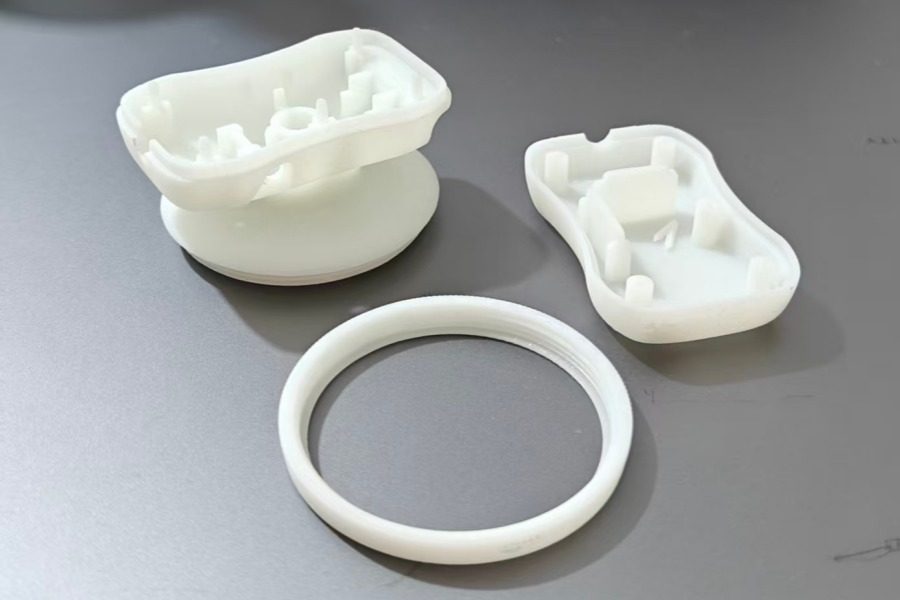

Rapid Prototyping & Flexible Production

We accelerate product development and provide scalable manufacturing for custom electronics.

Rapid prototyping: 3D printing, vacuum casting, and functional sample creation.

Pilot to mass production: Flexible small-batch runs up to full-scale manufacturing.

Design validation: Quick iteration and testing cycles reduce development risk.

OEM/ODM services: Support from design review to mass production for efficiency and quality.

Collaboration: Close communication with clients to tailor processes for unique product requirements.

Manufacturing Process & Quality Assurance

Our manufacturing process is designed to ensure precision, reliability, and accountability at every stage. From raw material selection to final assembly, each step is controlled, tested, and fully traceable, providing customers with confidence in both product performance and long-term quality.

Custom Process

Receive customer designs or samples and conduct DFM and feasibility evaluation.

Produce prototypes or sample units and send to the customer for testing and approval before mass production.

Source verified plastics, metals, and electronic components from trusted suppliers.

Build precision molds and perform injection molding with strict quality control.

Manufacture PCBs, perform SMT/DIP assembly, and integrate miniaturized components.

Carry out full-scale molding, PCB assembly, and final integration under controlled processes.

Perform functional, reliability, and compliance testing to ensure every product meets standards.

Conduct cosmetic checks, safe packaging, and arrange logistics for global delivery.

Quality Assurance & Traceability

Functional Testing

Verify electrical, mechanical, and software functions against specifications to ensure proper operation.

Reliability Testing

Conduct environmental stress tests including temperature cycling, humidity, vibration, drop, and lifecycle testing.

Compliance Validation

Ensure products meet global standards such as FCC, CE, RoHS, UL, and other industry-specific requirements.

Traceability System

Every production batch is logged with detailed materials, process parameters, assembly records, and inspection results.

Documentation & Reporting

Provide complete test reports, certificates, and process records for full accountability and future reference.

Performance & Safety Testing

Specialized tests such as battery safety, EMC/EMI, and operational performance under stress, ensuring the product is safe, stable, and reliable.

Meet our success stories

We provide custom electronic device services across multiple industries, including consumer electronics and professional equipment. Our goal is to offer clients a one-stop solution, saving valuable time, cost, and effort throughout the product development and manufacturing process.

From design support, advanced injection molding, PCB fabrication, component procurement, assembly, to final testing, we handle every step of the workflow. In addition, we assist in sourcing other necessary components, such as industry-specific electronic parts or hardware accessories, ensuring a seamless and efficient production process.

By offering this comprehensive service, we help clients accelerate development cycles, reduce supply chain complexity, optimize costs, and bring high-quality products to market faster, all while maintaining flexibility to meet unique project requirements.

⭐️⭐️⭐️⭐️⭐️

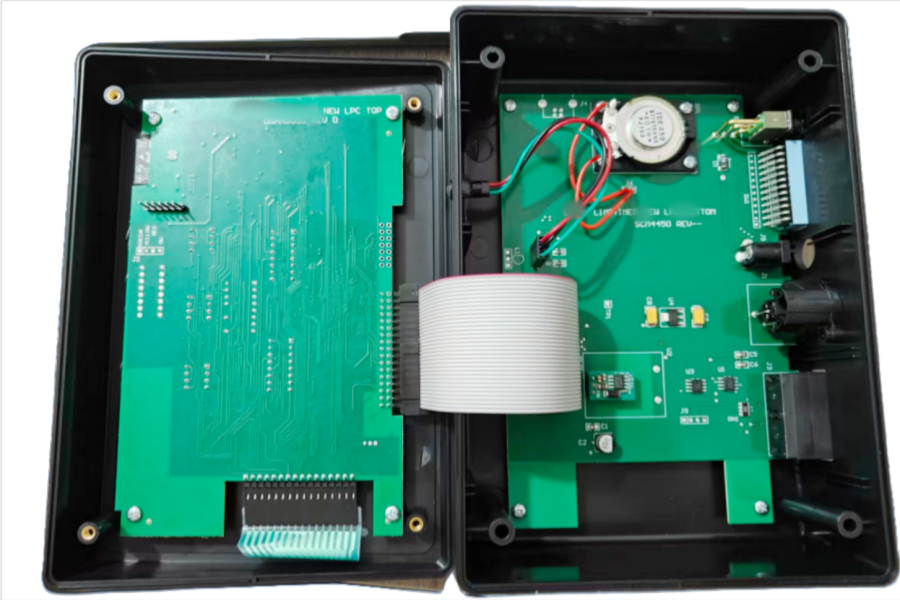

Professional Equipment – United States

One of our American clients specializes in professional conference equipment. Initially, they were cautious and only entrusted us with simple enclosure parts. Over time, as they became familiar with our capabilities, they gradually expanded the scope to include PCB fabrication, assembly, and full device integration.

We successfully delivered high-quality products that met their expectations, earning their trust. Today, the client sends us samples of other products from the United States, asking us to handle assembly and functional testing. Their products, manufactured with our support, are now sold globally, demonstrating the reliability and consistency of our services.

⭐️⭐️⭐️⭐️⭐️

Audio Device Replication – United States

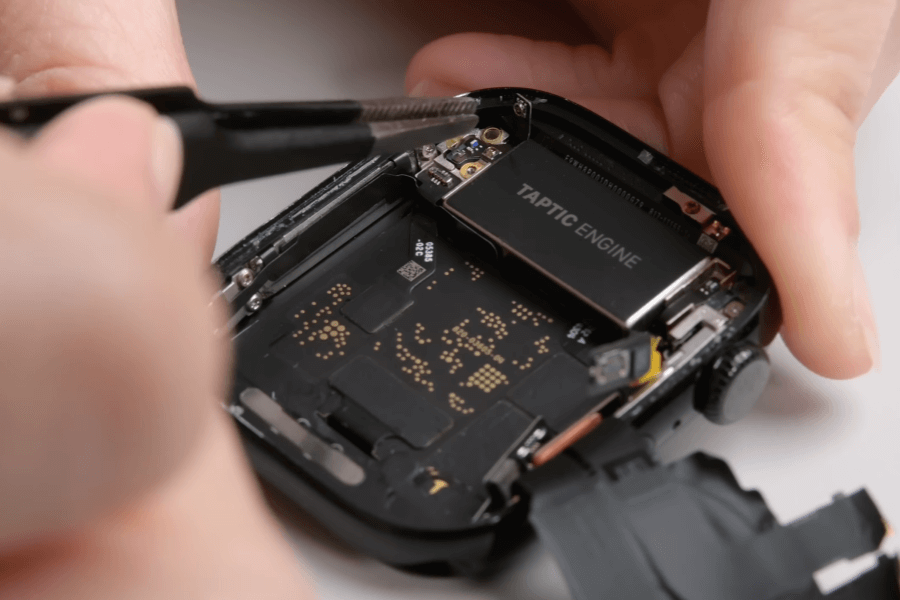

A client we first engaged with over ten years ago approached us recently with a special request. They wanted to replicate a bestselling auditory device from a decade ago, but the original production data was no longer available.

The client provided only a single previous product sample. Leveraging our reverse engineering, PCB data capture, and prototyping capabilities, we successfully recreated the device. After confirming the prototype, production has now commenced. This project highlights our ability to revive legacy products and deliver fully manufacturable, high-quality solutions even when original designs are lost.

⭐️⭐️⭐️⭐️⭐️

Urgent Component Procurement – Poland

A Polish client initially only wanted to purchase a few automotive testing tool balls. Attempts to source them via online platforms like AliExpress were unsuccessful. Later, they found us through Google and requested our assistance with procurement.

With a tight deadline, our team responded promptly, sourced the required items, and ensured delivery within the client’s specified timeframe. By using our services, the client not only saved time and money but also experienced reliable, responsive service. This case demonstrates our commitment to providing flexible, solution-oriented support for urgent customer needs.

FAQ

What types of electronic devices can you manufacture?

We provide custom manufacturing for a wide range of electronic devices, including consumer gadgets, wearable devices, smart home products, and professional equipment for industrial or specialized applications.

Can you handle both small pilot runs and large-scale production?

Yes. Our facilities are fully equipped for flexible production, from prototypes and small-batch runs to full-scale OEM/ODM production.

Do you offer design support or help with product replication?

Absolutely. We can transform customer-provided designs or existing samples into production-ready solutions while providing reverse engineering, design optimization, and prototyping services.

How do you ensure the quality and reliability of custom devices?

Every device undergoes rigorous functional, reliability, and compliance testing, including environmental, drop, and cycle tests, to meet standards such as FCC, CE, and RoHS.

Do you handle PCB fabrication and component procurement?

Yes. We offer high-density PCB fabrication, electronic component sourcing, and integration. We also assist with procuring specialized components or hardware to ensure a seamless production workflow.

What injection molding capabilities do you offer?

We specialize in precision injection molding, including two-shot/multi-color molding, insert molding, soft-touch overmolding, IML/IMF, high-gloss painting, and textured finishes for durable and visually appealing housings.

How do you protect intellectual property during product replication?

All work is performed strictly on customer-owned designs and samples, with full respect for intellectual property. Confidentiality and data security are maintained throughout the process.

How can your services help reduce time and cost in product development?

By providing end-to-end, one-stop services—from design support and prototyping to assembly, testing, and component procurement—we streamline development, reduce supply chain complexity, and accelerate time-to-market while optimizing overall costs.