Medical Electronic Devices

We specialize in precision manufacturing for medical electronic devices —

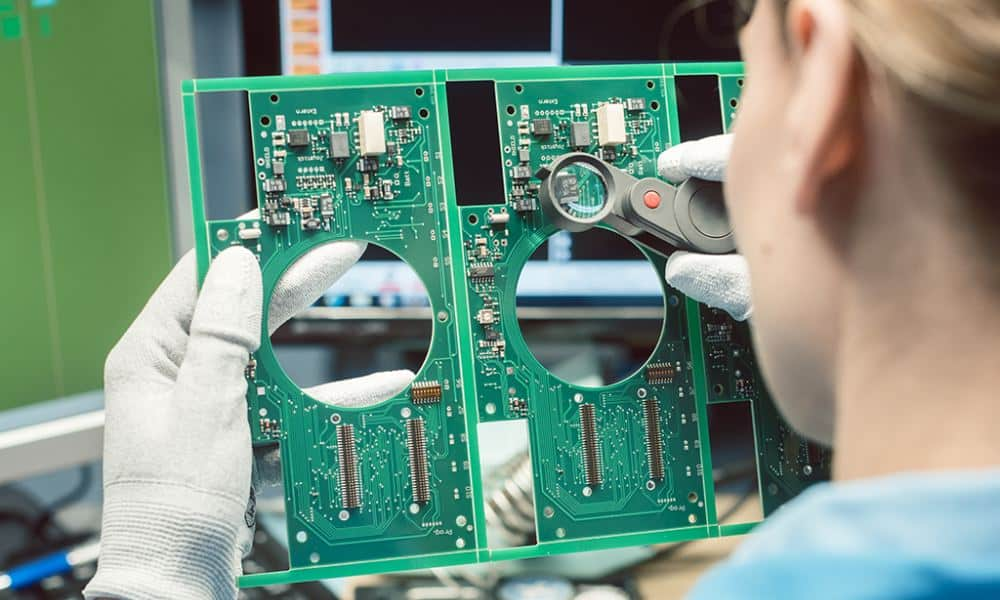

from micro plastic parts and PCBA integration to fully assembled, compliant products.

Medical Electronic Equipment

At CINDY Mould, we go beyond contract manufacturing — we provide precision-engineered solutions for medical-grade electronic devices, combining plastic molding, PCB assembly, and complete system integration.

With cleanroom molding environments, metal-insert overmolding, and tight-tolerance assembly lines, we ensure each component achieves superior safety, durability, and biocompatibility for use in demanding healthcare applications.

Our R&D and engineering teams apply advanced mold-flow simulation, CNC machining, and functional reliability testing to help clients accelerate development while maintaining strict ISO 13485 and FDA compliance.

From low-volume prototypes to mass-production OEM/ODM programs, we deliver turnkey manufacturing solutions that help global medical brands launch faster, perform more reliably, and meet international quality standards.

Our Capabilities

Delivering reliable, high-quality solutions for Medical Electronic Devices.

Plastic + PCB

- Integrated production of housings and PCB assemblies

- Ensures precise fit of structure and electronics

- Streamlined supply chain

Custom Assembly

- Tailored injection molding for medical housings

- Modular assembly for multiple device types

- Flexible for prototypes and mass runs

Tooling Support

- In-house mold design and optimization

- Control wall thickness, fastening, and heat dissipation

- Engineering support for manufacturability (DFM)

Testing & Validation

- Electrical and mechanical reliability testing

- Life cycle and durability assessments

- Compliance with CE/FCC/UL standards

Production Scalability

- Support for low-volume prototypes and high-volume runs

- Automated assembly lines for efficiency

- Flexible capacity to meet urgent delivery

Customer Support

- Collaborative R&D with clients

- Transparent project management

- After-sales technical service

Product Showcase

Explore our representative medical electronic components —

from transparent housings to miniature modules — designed to meet healthcare device needs.

Thermometer housing

Blood pressure monitor housing

Finger pulse oximeter housing

Smart bracelet case

Oximeter housing

Blood glucose meter housing

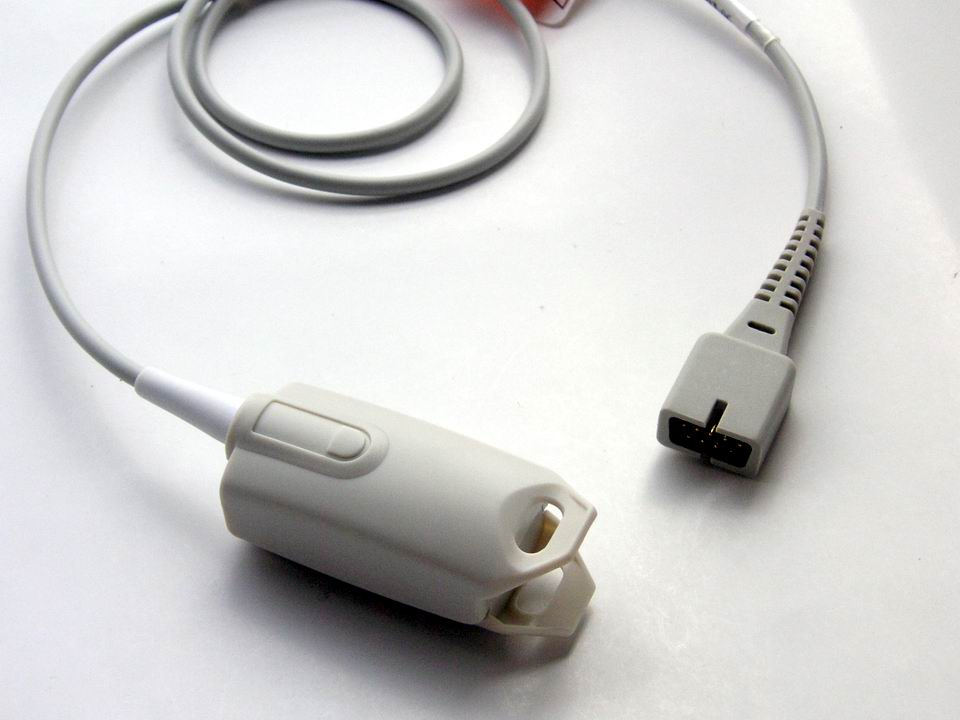

Finger clip oximeter

Infrared Thermometer

Finger pulse oximeter

Defibrillator

Pulse Oximeter

Digital Blood Pressure Monitor

Application Scenarios

Explore the applications of our medical electronics in different scenarios and provide solutions for various medical needs.

Home Care

Small medical electronics offer convenient, accurate home health solutions for easy monitoring and management of key health indicators.

Blood Glucose Monitoring: Compact meters, easy to use (even for the elderly). Get accurate readings quickly with a small fingertip blood sample.

Vital Sign Tracking: Mini pulse oximeters clip onto fingers, monitoring blood oxygen and heart rate in real time to detect abnormalities.

Health Data Logging: Connect to mobile apps to auto-record data into trend charts—easy to share with doctors during consultations.

Outdoor First Aid

Small medical electronics are lightweight and easy to store, providing quick initial health checks for unexpected outdoor health issues.

Wound & Vital Check: Mini sensors enable fast detection of wound conditions or basic vital signs (e.g., heart rate) at the scene.

Space-Saving Storage: Ultra-compact design fits in small first-aid kits—no extra bulk for hikers, campers, or travelers.

Rapid Response: Simple one-button operation helps get key health data quickly, buying time for follow-up care.

Personal Health Management

Compact wearable or portable medical electronics let you track health data anytime, supporting proactive daily health management.

Real-Time Tracking: Smart bands monitor heart rate, step count, and sleep quality 24/7—no need for bulky devices.

Data Sync: Auto-connects to mobile apps to organize data into easy-to-read trends (e.g., weekly sleep patterns).

Long Battery Life: Small size with extended battery—no frequent charging, perfect for all-day or travel use.

Customer Case Studies

These cases highlight how CINDY Mould supports medical electronics brands with end-to-end manufacturing solutions — from DFM and tooling to cleanroom molding, ESD-safe assembly, and functional validation.

Portable Blood Pressure Monitor

Challenge: The client required a compact, biocompatible housing and PCB integration solution compliant with ISO 13485 and CE standards.

Our Support: CINDY Mould carried out full DFM analysis and tooling optimization for the enclosure, ensuring tight dimensional control. Production was executed in a Class 10K cleanroom using medical-grade resin. Our team also performed PCB assembly and functional reliability testing to validate long-term stability.

Mini Diagnostic Module for First-Aid Kits

Challenge: A medical supplier needed a miniature diagnostic module combining PCB, molded parts, and connectors that could endure field use.

Our Support: We applied micro-injection molding for high-precision housings and performed assembly on an ESD-safe modular line with custom jigs. Each batch underwent electrical and mechanical validation, confirming compliance with CE and RoHS requirements.

Wearable Health Tracker

Challenge: The project required a slim, waterproof, and biocompatible housing that maintains precise PCB and sensor alignment in high-volume runs.

Our Support: CINDY Mould implemented dual-shot molding to combine rigid and soft materials for perfect sealing. Comprehensive DFM reviews and mold-flow simulations optimized manufacturability. Assembly and inspection were performed in ESD-protected cleanroom zones, supporting production of 100,000+ units with consistent yield.

Quality & Compliance System

Every step of our medical electronics manufacturing process is governed by international quality standards and strict process control — ensuring safety, reliability, and full traceability from material selection to final shipment.

ISO 13485 Certified

Certified QMS for medical device manufacturing.

Ensures consistent processes and documentation control.

Regularly audited for continual improvement.

Process Control & Traceability

End-to-end monitoring from molding to assembly.

Batch records ensure full traceability.

Real-time process data supports quality stability.

Material Compliance

All materials tested under ISO 10993 & RoHS.

Guarantees product safety for medical contact.

Validation reports traceable by batch.

ESD & Cleanroom Controls

Class 10K cleanroom for sensitive assemblies.

ESD-protected zones prevent static discharge.

Regular audits maintain controlled environment.

Reliability Testing

100% in-process inspection and validation.

Electrical, mechanical & life cycle testing.

Guarantees long-term performance stability.

CE / FCC / RoHS Compliance

Products certified for international markets.

CE / FCC / RoHS conformity verified by 3rd-party labs.

Ensures global export readiness and legal compliance.

Partner with CINDY Mould for Your Next Medical Electronics Project

From concept validation to mass production,

we provide precision, compliance, and reliability at every stage of manufacturing.