Reliable Manufacturing for Security & Communication Devices

CINDY Mould provides certified manufacturing solutions for secure and reliable communication devices — from housing to full system assembly.

Secure Manufacturing Expertise

🔹 Comprehensive Integration

CINDY Mould provides end-to-end manufacturing for secure communication devices — covering precision plastic housings, encrypted PCB modules, and full system assemblies. Every process is optimized to ensure data protection, signal stability, and long-term reliability.

🔹 Engineering & Validation

Our R&D and tooling engineers perform DFM/DFA optimization, mold-flow simulation, and shielding structure design. Each assembly undergoes EMI/EMC, vibration, and thermal validation to guarantee consistent performance and compliance with CE and ISO standards.

🔹 Controlled Production Environment

Assembly and inspection take place in ESD-protected and dust-controlled zones. Real-time process monitoring ensures full traceability, while anti-tamper safeguards maintain product integrity throughout manufacturing.

🔹 Collaborative Development

We work closely with clients from concept to mass production — offering modular, scalable solutions that shorten lead time, improve reliability, and meet the evolving demands of global communication industries.

Applications in Security & Communication

Real-world applications where secure design meets reliable manufacturing.

From financial transactions to industrial networks, secure communication is the backbone of trust. Our integrated plastic + PCB assemblies are designed with encryption, shielding, and compliance testing to ensure devices remain reliable in the most demanding applications.

Secure Payment Terminals

Trusted modules for safe financial transactions worldwide.

- 🔒 Challenge: POS and ATM devices are frequent targets of tampering and fraud.

- ⚙️ Solution: Secure chip integration, multi-layer shielding, and intrusion-resistant housings.

- 💡 Value: Certified to PCI DSS, EMV, CE, and FCC standards for global deployment.

- 🏧 Applications: ATMs, handheld POS devices, credit card readers, mobile payment terminals.

Smart Access & Authentication

Secure, encrypted hardware to protect every entry point.

- 🧠 Challenge: Identity theft and unauthorized entry threaten modern access systems.

- 🛡️ Solution: Encrypted PCBs with tamper-proof housings, EMI shielding, and secure chips.

- ✅ Value: International compliance ensures long-term reliability and trust in sensitive environments.

- 🚪 Applications: Smart locks, biometric gates, corporate access cards, industrial safety doors.

Industrial Communication Systems

Resilient data transfer in demanding industrial environments.

- ⚡ Challenge: Harsh factory conditions with EMI, vibration, and extreme temperatures.

- 🔧 Solution: Shielded PCB assemblies, reinforced housings, high-reliability connectors, and ESD protection.

- 🔒 Value: Reliable, secure data transfer ensures zero downtime in mission-critical operations.

- 🏭 Applications: Factory automation, smart energy grids, critical monitoring systems.

IoT Security Gateways

End-to-end protection for the growing Internet of Things.

- 🌐 Challenge: Edge devices in IoT networks face constant security vulnerabilities.

- 🔒 Solution: Integrated antennas, secure elements, encrypted PCBs, and tamper-proof casings.

- ✅ Value: CE, FCC, and UL certified for global deployment with extended lifecycle reliability.

- 📡 Applications: Smart homes, healthcare monitoring devices, connected vehicles, logistics tracking.

Our Core Technical Advantages

Six proven strengths define how CINDY Mould ensures reliability, data protection, and performance for every secure communication device.

Shielded PCB Assembly

- Multi-layer PCB with EMI / ESD protection

- Stable signal transmission under interference

- Ideal for secure payment and industrial systems

Tamper-Proof Housing

- Injection-molded, anti-intrusion design

- Protects sensitive chips from tampering

- Enhances reliability in critical devices

Encryption-Ready Integration

- Supports cryptographic chips and secure elements

- End-to-end encryption for IoT & financial devices

- Reduces risk of data breaches

Global Compliance Testing

- Certified to CE, FCC, UL, and EMC standards

- Comprehensive EMI / ESD and safety verification

- Ready for international deployment

High-Reliability Connectors

- Resistant to vibration, heat, and long-term wear

- Ensures stable connection in industrial applications

- Compliant with automotive-grade standards

Full Lifecycle Quality Assurance

- 100% inspection from PCB to full assembly

- Environmental and mechanical stress testing

- Guarantees reduced failures and higher trust

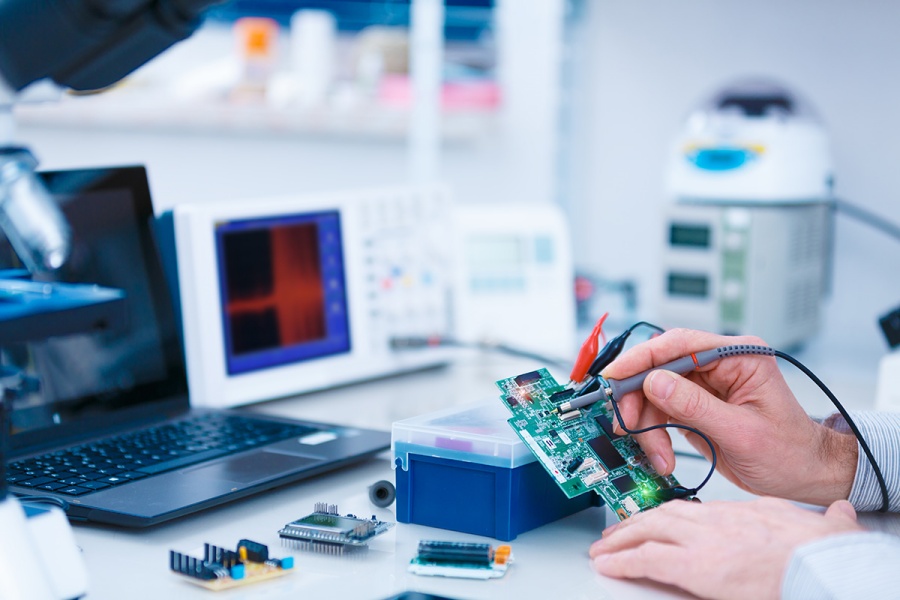

Quality Control & Compliance

Every product undergoes rigorous electrical, EMI/ESD, and functional testing to ensure consistent reliability and compliance with global standards.

Reliable Testing Solutions

Each secure communication module undergoes electrical, EMI/ESD, and functional testing to ensure consistent performance and compliance with international standards.

•

Ensures stable power integrity and current performance under stress.

•

Protects against electromagnetic interference and electrostatic discharge.

•

Verifies that all assemblies perform flawlessly under real-use conditions.

•

Simulates extreme environmental and mechanical conditions to guarantee long-term durability.

International Compliance

Our products are certified to global standards including CE, FCC, UL, RoHS, and ISO9001 — ensuring reliability, safety, and market readiness across worldwide applications.

•

Certified with CE, FCC, UL, RoHS, and ISO9001 for international market acceptance and regulatory compliance.

•

Meeting the strictest regional regulations and certification frameworks for smooth global deployment.

•

Providing complete test and compliance reports for every batch, ensuring full transparency and traceability.

•

Maintaining up-to-date certification records to ensure continuous compliance across all markets.

Reliability Assurance

Our products undergo lifecycle and environmental stress tests to guarantee long-term durability and reliability, ensuring they perform optimally even in harsh conditions.

•

Simulating real-world conditions to validate long-term product durability and mechanical integrity.

•

Testing resistance to temperature, humidity, and vibration to ensure consistent performance over time.

•

Applying rigorous inspection at every production stage to maintain the highest reliability standards.

•

Evaluating performance in real-world scenarios to guarantee user confidence and lasting value.

Traceability & Documentation

We ensure full traceability throughout every stage of production — from material sourcing to final inspection — guaranteeing transparency, accountability, and compliance in every shipment.

•

Every product’s complete lifecycle is documented, from raw material sourcing to final assembly, ensuring total transparency and accountability.

•

Comprehensive quality and compliance reports are generated for each batch, providing verifiable data for customer review.

•

All inspection results are recorded and archived, ensuring every unit meets stringent standards before shipment.

•

Each product includes up-to-date certification files confirming compliance with international industry standards.

Customer Case Studies

Explore how CINDY Mould’s integrated manufacturing helps global brands achieve reliability, compliance, and faster time-to-market.

Secure Payment Terminal

- Challenge: Financial-grade devices required tamper-proof housings and EMI/ESD protection.

- Solution: Engineered shielded enclosures, integrated secure PCB modules, and completed CE/FCC verification.

- Result: Achieved full compliance, reduced failure rate by 30%, and enabled global rollout.

Industrial Communication Module

- Challenge: Needed reliable, high-speed data transmission in harsh industrial environments.

- Solution: Designed IP-sealed connectors and conducted multi-cycle vibration and temperature testing.

- Result: Improved durability, extended product lifespan by 25%, and maintained zero data loss during operation.

Smart Access Control Device

- Challenge: Required secure authentication with low power consumption for building systems.

- Solution: Integrated RFID/NFC modules within tamper-proof plastic housings and optimized PCB layout.

- Result: Lowered power use by 20%, enhanced security, and achieved stable long-term field performance.

Customer Support & After-Sales Service

We provide complete support throughout the product lifecycle — covering technical help, repair, warranty, upgrades, training, and feedback tracking.

📞 Technical Support

- Troubleshooting during product use

- Answering operational questions

- Providing manuals and online support

Support channels: phone, online chat, email, remote assistance.

🔧 Product Repair

- Professional repair for malfunctioning products

- Fast restoration to minimize downtime

- Extend lifecycle with proper repair solutions

Options: free or paid repair, depending on warranty coverage.

🛡️ Warranty Service

- Comprehensive coverage for 1–3 years

- Protection against manufacturing defects

- Repairs, replacements, or returns within warranty

Coverage: repairs, replacement parts, product exchange.

⚙️ Product Upgrades

- Enhancing existing product features

- Keeping devices up-to-date with new tech

- Extending product value via upgrades

Options: software updates, hardware upgrade packages.

📚 Training & Technical Guidance

- Training on product operations

- Best-practice guidance for teams

- Maximize performance and uptime

Formats: online training, video tutorials, on-site workshops.

💬 Customer Feedback & Issue Tracking

- Structured feedback collection

- Issue logging and end-to-end tracking

- Continuous follow-up for resolution

Channels: hotline, online surveys, social media.

Let’s Build Secure & Reliable Solutions Together

From design to manufacturing, CINDY Mould provides one-stop solutions that combine reliability, compliance, and cost efficiency — helping you bring better products to market faster.