Automotive Components Manufacturing & Assembly

Automotive

CINDY Mould specializes in high-precision automotive manufacturing, providing a complete range of solutions for Plastic Automotive Parts, Functional Mechanical Components, and Automotive Electronics Assembly. Equipped with advanced injection molding machines, metal-insert overmolding capabilities, and precision assembly lines, we ensure every part meets the highest industry standards for accuracy, durability, and performance.

Our experienced R&D and engineering team works closely with clients to design, prototype, and produce complex automotive components, from exterior and interior plastic parts to functional assemblies like safety mechanisms and in-vehicle electronics modules. Using CNC machining, mold flow analysis, and rigorous quality control, we deliver reliable, high-quality solutions that enhance production efficiency and vehicle performance.

Serving global customers, CINDY Mould is committed to providing customized automotive parts solutions with on-time delivery and professional support, helping automotive manufacturers achieve superior results in plastic parts, functional components, and electronic assemblies.

Our cases

Air Ducts / Interior Plastic Parts

Headlamp Housing / Headlight Frame

Fog Lamp Bezel / Fog Light Cover

Front Bumper

Rear Bumper / Bumper Cover

Engine Cover, Dashboard Panel, Radiator Grille, Mounting Bracket

We provide contract manufacturing services for high-precision automotive plastic parts, including exterior and interior components such as mirror housings, dashboards, door panels, and trim parts. Our capabilities cover injection molding, overmolding, LSR molding, and secondary operations such as decorating, painting, and surface treatment. Supported by DFM guidelines and mold flow analysis, we ensure optimal manufacturability, high dimensional accuracy, and consistent surface quality. Serving tier-1 automotive customers worldwide, we deliver reliable, durable, and high-performance plastic components tailored to diverse applications.

Safety Belt Buckle

Window Switch Housings

Door Handles

Fuel Tank Cap

Central Control Buttons

Wiper Components

Our factory specializes in manufacturing functional and safety-critical components that combine plastic and metal inserts, including seat belt buckles, door lock parts, pedals, adjustment knobs, and other mechanical assemblies. We offer injection molding with metal insert overmolding, precision assembly, and post-processing operations to meet strict tolerance, load-bearing, and durability requirements. With comprehensive DFM support, in-house prototyping, and rigorous quality testing, we provide automotive functional parts that comply with industry safety standards and long-term reliability expectations.

Vehicle Controller Unit (VCU)

OBD car networking terminal

Driving recorder

Car charger

Car rearview camera

Car navigation system

We provide complete assembly services for in-vehicle electronics modules, including products such as dashboard control units, ECU brackets, sensors, cameras, and infotainment displays. Our services cover PCB assembly, module integration, injection-molded housing assembly, and full functional testing, ensuring precision, performance, and reliability. With a dedicated engineering team and advanced production lines, we support rapid prototyping, custom design adjustments, and volume production while maintaining rigorous quality control. This enables us to deliver high-quality automotive electronics solutions to global tier-1 customers efficiently.

Our Capabilities

We specialize in precision manufacturing and assembly of automotive electronic components, delivering reliable, high-quality solutions for in-vehicle systems.

Precision Injection Molding

High-precision injection molding for automotive electronic housings and interior components.

Electronic Component Assembly

Reliable assembly of in-vehicle electronic modules with industrial-grade standards.

DFM & Mold Flow Analysis

Design support and mold flow analysis to ensure optimal manufacturability and reliability for electronic parts.

Modular Components & Assemblies

Flexible modular design for easy integration of automotive electronic systems.

Durability & Reliability Testing

Industrial-grade testing ensures electronic modules withstand temperature, vibration, and long-term use.

Rapid Prototyping & Small Batch Production

Quick production of prototypes and small batches for electronic module validation and design iteration.

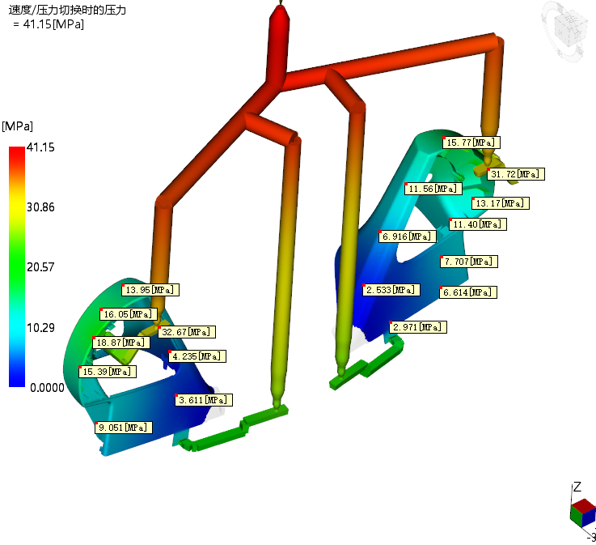

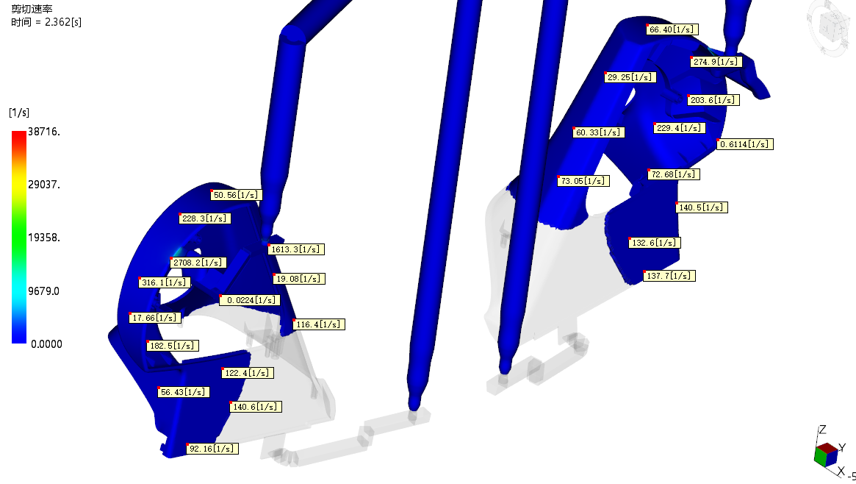

Moldflow Analysis Case

Automotive Rearview Mirror

The automotive rearview mirror housing is a precision injection-molded component made of PMMA + ASA, combining high optical clarity for transparent areas and UV-resistant, durable ASA for structural support. This component is critical for vehicle safety and aesthetics, integrating functional design with premium surface quality.

Manufacturing Challenges:

Wall Thickness Variation: The housing has thin edges and thicker support ribs. The significant thickness differences can lead to uneven shrinkage and warpage during cooling.

Warp Control: Extended or protruding features are prone to distortion, which can affect both assembly fit and optical alignment.

Flow and Filling Issues: Complex internal ribs, mounting bosses, and transparent areas can cause short shots, weld lines, and trapped air, especially in PMMA sections sensitive to temperature fluctuations.

Gate Placement and Mold Design: Proper gate locations and optimized cooling channels are essential to ensure uniform filling, high surface quality, and minimal optical defects.

Dimensional Accuracy: Mounting interfaces and clip features must maintain tight tolerances for precise assembly to vehicle brackets, sometimes requiring secondary operations or high-precision mold design.

Benefits of Moldflow Analysis:

By performing Filling, Pressure, and Warpage simulations, our engineers can predict potential defects, optimize gate locations, fine-tune injection parameters, and design effective cooling systems. This ensures consistent part quality, reduced warpage, and improved production reliability, even for complex geometries and mixed-material components.

Supporting Clients’ Product Development and Manufacturing:

Moldflow insights allow clients to evaluate design feasibility, optimize manufacturing processes, and improve part quality across both existing and new mirror designs. By identifying challenges early, we help reduce trial-and-error cycles, accelerate development timelines, and guarantee that mirrors are produced efficiently, reliably, and to the highest quality standards.

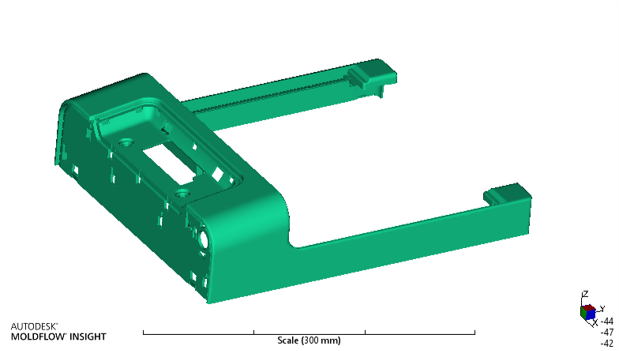

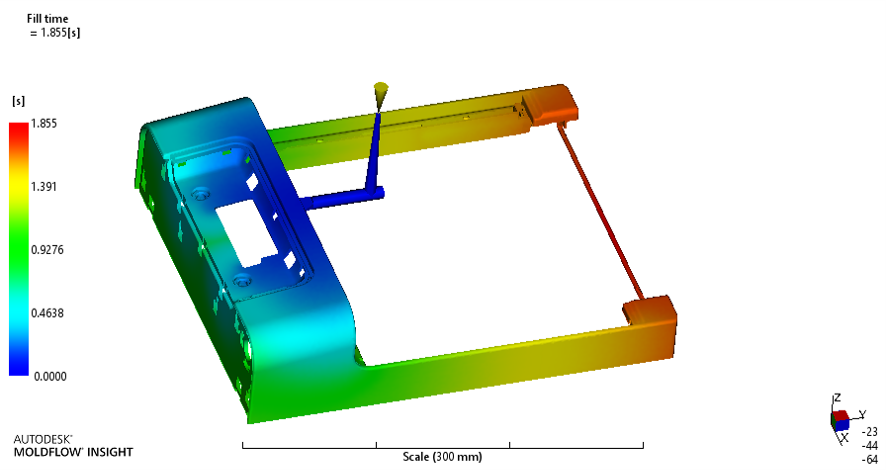

Automotive Electronics Housing

This automotive electronics housing is a complex injection-molded ABS component featuring open areas, mounting holes, and extended arms for structural support. The part serves as a bracket or enclosure for in-vehicle electronic modules, such as dashboard sensors, control units, or infotainment system components.

Manufacturing Challenges:

Wall Thickness Variation: Long arms and solid support sections create significant thickness differences, which can lead to shrinkage and warpage.

Warp Control: Extended structures are prone to distortion during cooling, requiring careful mold cooling design and fixture planning.

Flow Difficulties (Filling): Central frames and support ribs can cause uneven material flow, potentially resulting in short shots, voids, or burn marks.

Gate Location and Type: Proper gate placement is critical to ensure uniform filling, especially in extended areas.

Dimensional Accuracy & Post-Processing: Mounting holes must maintain precise alignment, possibly requiring secondary machining or precise mold design.

Benefits of Moldflow Analysis:

By simulating Filling, Pressure, and Warpage, our engineers can optimize gate locations, cooling systems, and injection parameters. This helps reduce defects, control warpage, and improve dimensional accuracy, ensuring a stable, high-quality production process.

Supporting New Product Development:

The insights from our moldflow analysis also make it easier to explore new designs. By understanding potential challenges early, clients can iterate faster, adjust designs confidently, and bring innovative electronic housings to market with less trial and error.

Looking Ahead

CINDY Mould, in partnership with our parent company JINYI Moulding, has been delivering over 1 million high-precision plastic components annually to clients in more than 30 countries, along with hundreds of molds produced each year. Leveraging advanced technology, experienced engineers, and state-of-the-art production equipment, we ensure every product meets the highest standards of quality and reliability.

Looking ahead, we are committed to expanding our capabilities in smart assembly, innovative materials, and sustainable manufacturing, helping global automotive partners develop the next generation of vehicles with efficiency, precision, and confidence. Our goal is to continue delivering cutting-edge solutions that empower our clients to bring innovative automotive products to market faster and more reliably.